Modify the ears of the mag block so it doesn’t hit the bolt carrier. I just used a disc sander and ground down the ears.

BTW, this is a Hahn bottom loading mag block I’m modifying….but should be similar process for most mag blocks.

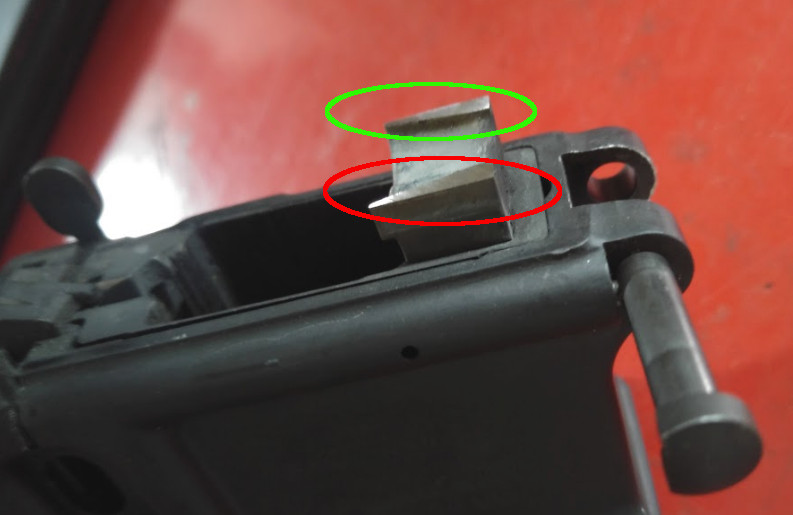

Picture below shows how high my ears are after grinding.

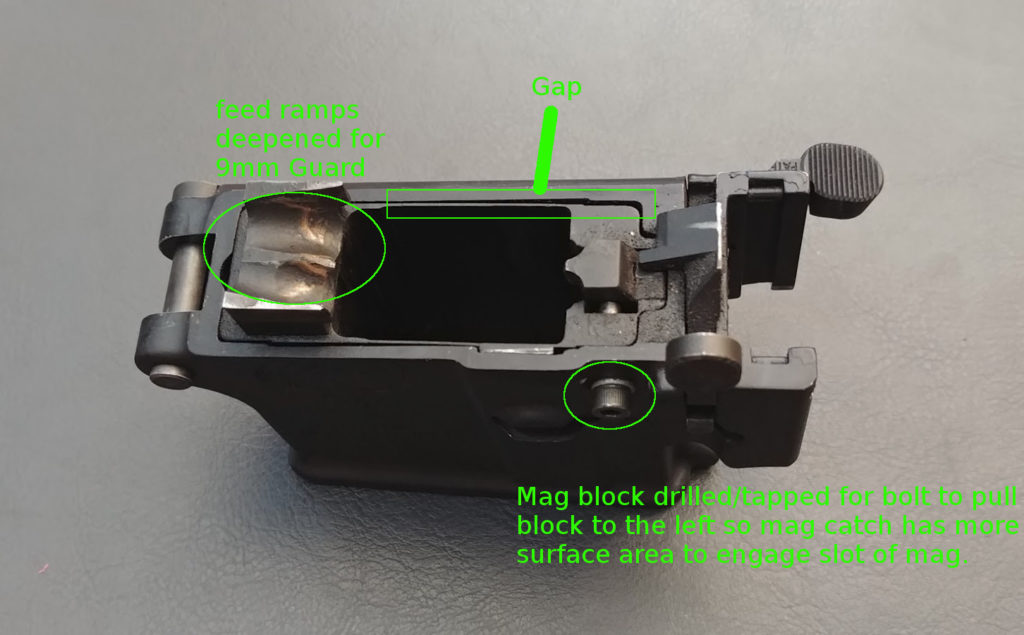

Modify mag catch for unmodified Colt mags. I initially started at about .040″ which cleared but was having malfunctions when firing as I think the mags were moving and rubbing on the carrier. You can see i’m close to .100″ now. I think if I were to do it over, I would start testing around .060 – .080 now….but what I have now is working so I’ll leave it alone.

Removing more material from the mag catch required the feed ramps to be deepened on my Hahn mag block. I happen to be using an MGI lower and a 556 mag well with Hahn block that has always been a little small for this magwell which I remedied years ago by bolting the mag block in place.

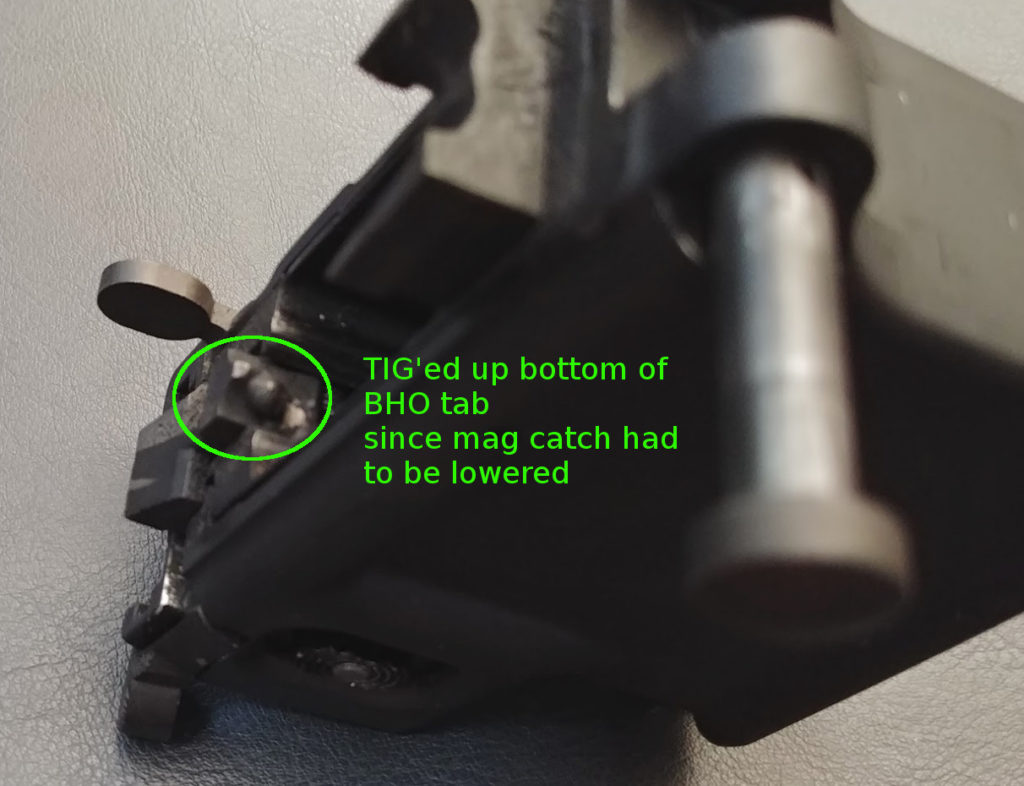

Lastly, since the mag catch was lowered, I lost bolt hold open functionality. Little TIG welding underneath the ‘tab’ fixed that.

Update 5/2024

I did the modifications above back in 2018 before CMMG addressed this and came out with a kit to allow you to use unmodified Colt mags with their straight blowback Mk9 lower. One feature that I did not do back in 2018 was to prevent the mag from being over-inserted by modifying the feed ramp. It appears CMMG has addressed this but they have two different kits depending on if you are using 1. Colt / Metalform mags https://cmmg.com/parts-kit-mk9-9mm-radial-delayed-blowback-colt-metalform-mags or 2. ASC / CPD mags https://cmmg.com/parts-kit-mk9-9mm-radial-delayed-blowback-asc-cpd-mags. I think the latter are cut lower…hence the different feed blocks. This is just my speculation as I have almost all Colt / Metalform mags and only 1 CPD mag. I do know the followers are also different but think it has to with the front cut.

The main reason I am re-visiting this is that I happened to come across a good deal on the magwell below so I ordered the parts intended for the Mk9 lower to see if I could modify them for my MGI lower.

Update 6/2/2024

Ran setup above at SMG match but decided to take a chance and use the Warthog flat spring without testing first. I had zero issues stripping rounds off with that buffer spring and the Colt mags and drums pictured above.

Cyclic rate results below using the Warthog spring. Configuration below using the modified fluted MP5K barrel.

Configuration below using modified Odin Works SS barrel with standard chamber. This is quietest configuration of the 4. I don’t know if it has anything to do with the fluted chamber on the 3 other configurations as I would occasionally hear ‘popping’. While it wasn’t happening with this setup. I can’t mount my CT9KS to the other upper since the diameter is too large to fit inside the BRT handguard w/ the recessed MP5K barrel so I couldn’t test it without tearing it apart.

Configuration below using the modified fluted MP5K barrel.

Configuration below using the modified fluted MP5K barrel.

Update 6/22/2024

I didn’t like how I have been getting some loud pops w/ the fluted barrel and wanted to try my old CMMG custom barrel and got some interesting results:

I took some pictures of the extension with a bore scope and it doesn’t appear to be worn. I am not too motivated to remove the extension off the barrel at this time. Maybe another day.

While it is faster, it is still in the 600’s so I will probably just run it like this.