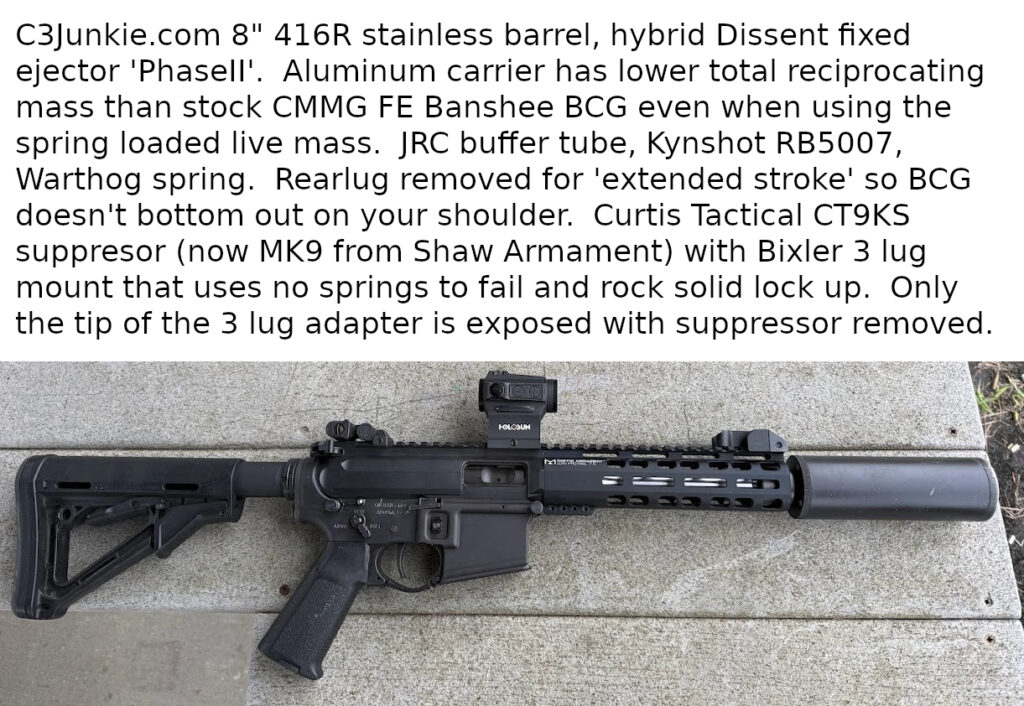

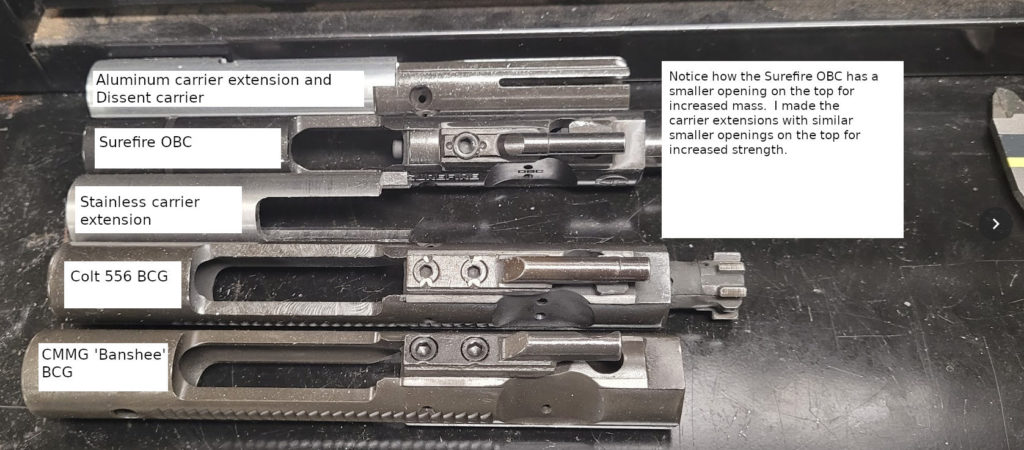

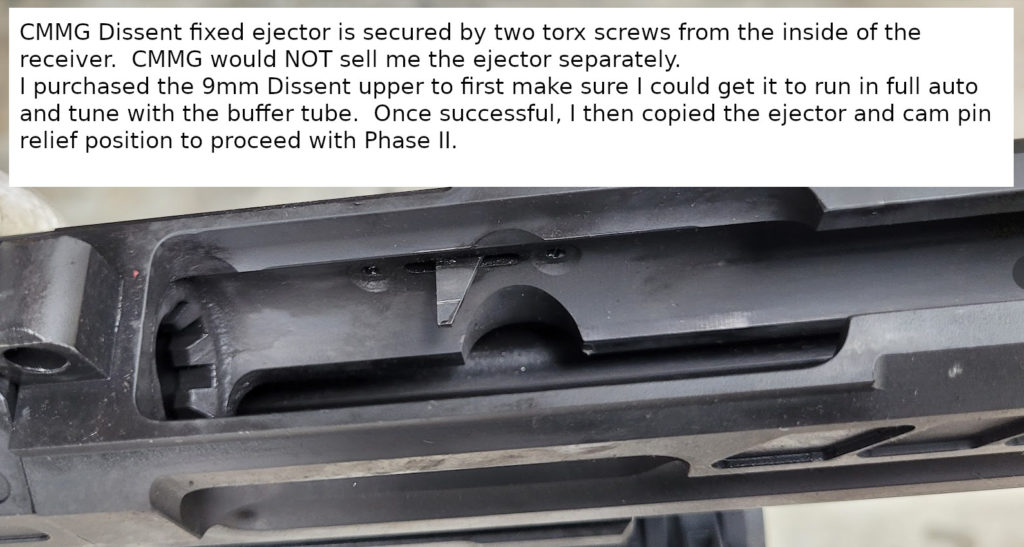

The goal is to have a smooth, reliable and tune-able delayed blowback full auto 9mm configuration for use with a RR / RDIAS or RLL utilizing the CMMG RDB (Radially Delayed Blowback) system. I presume it should also work with binary triggers but I don’t have any experience with those. Or if you just want to tune a 9mm fixed ejector Dissent. If you are reading this, you probably already know that the original CMMG ‘Guard’ (now referred to as the Banshee which is confusing since the Banshee term is also used for non-RDB configurations) has issues where the ejector spring fails. For me and many others, it seems to be around the 1000 round mark but I have seen people post as little as 300 rounds they have failures as well. See this link if you want more detail on the spring loaded ejector issues: CMMG RDB Ejector Spring Issues. The CMMG Dissent was released in 9mm and they finally went with a fixed ejector which is great but it is in a proprietary side charging upper that lost the ability to trip a sear and dropped the buffer tube so no more tuning with springs and buffers. Which BTW, the stock 9mm CMMG Dissent using their buffer-less setup with the internal recoil springs is NOT as smooth as an MP5 which isn’t surprising. So I made what I will call a ‘CE – carrier extension’ to trip the sear and use the buffer tube again. I initially made two of these, one from 7075 aluminum and one from stainless steel as I didn’t know if the aluminum would break from the shock (however, I believe that using a hydraulic buffer should aid in absorbing the shock based on all the high speed video I have done in the past).

As I have mentioned many times I was never impressed with the recoil impulse of an out of the box CMMG RDB. Is it better than a typical straight blowback AR9? Yes. Is it as smooth as an MP5 – no way. Let’s say it is like 60% there out of the box. Then using my combination documented here: My OLD 9mm CMMG RDB Setup which initially consisted of using a Tubb flat spring, A5 buffer tube and the Kynshot hydraulic RB5007 I would say it got it to about 90% of the MP5 but it also has a nicer cyclic rate than an MP5 with that configuration. Going to the .40SWbolt (60 degree vs 50 degree) for use in 9mm is what brought it to a point that matched the MP5 (in my opinion and several others that have shot my setup). However, the recoil impulse is so soft with the .40SW bolt, it isn’t moving fast enough for the spring loaded ejector to kick the brass out so a fixed ejector was required but then slotting the RDB bolt for the fixed ejector goes right across where the cam pin is and the bolt will eventually crack like mine did. So it all worked great but you do need to keep an eye on the health of the bolt.

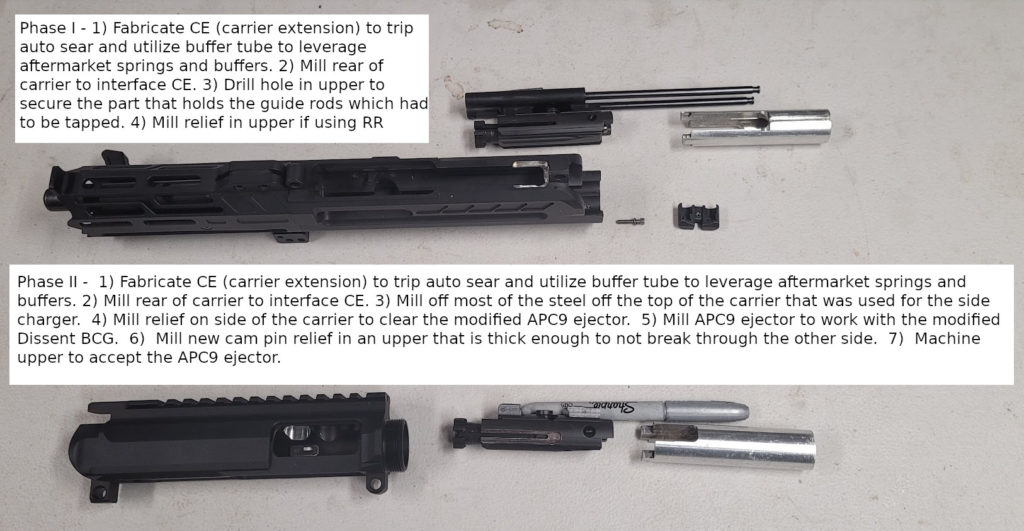

Phase I – Make a custom ‘carrier extension’ to allow the 9mm CMMG Dissent upper to trip the auto sear and utilize the buffer tube to leverage all the aftermarket springs / buffers.

Pros: This requires the least amount of machine work.

Cons: The Dissent BCG is heavier than the Phase II carrier so you are starting off with more reciprocating mass.

Upper is proprietary so may be fine if you like their side charging setup.

Upper is also heaver.

It is a NO-Go if you want to do an integrally suppressed build.

Tuning operating window is smaller due to the starting off with more reciprocating mass.

Phase II – Buy the 9mm CMMG Dissent BCG group which is currently available separately and retrofit / build out a new upper using a standard CH and existing CMMG ‘Guard / Banshee’ barrels or make my own RDB barrels.

Pros: Less reciprocating mass (at the time of me writing this, I think it is smoother than what is possible with Phase I)

Larger operating window for tuning

Compatible with other standard charging handles

Several upper receiver options (just need to be thick enough as detailed on this page)

Compatible with other side charging options like: https://typezerodesign.com/ or https://www.gibbzarms.com/ (not tested – may conflict with fixed ejector)

Compatible with making an integrally suppressed (SD) build

Cons: A lot more machine work

Note that with both Phase I and Phase II, I am making permanent modifications to some parts so forget about expecting any kind of support from CMMG or any other vendors mentioned or anyone including myself. If any of you want to copy me, it is at your own risk.

I have built over a dozen for friends and we are all running them 100% in full auto. I also make them for anyone interested. Contact Me if interested.

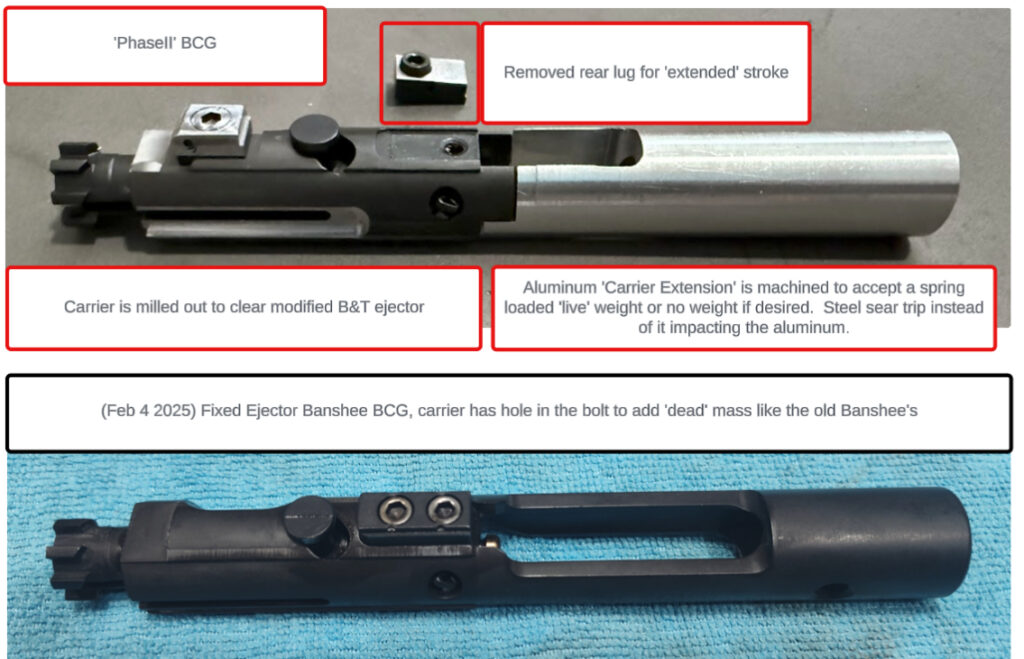

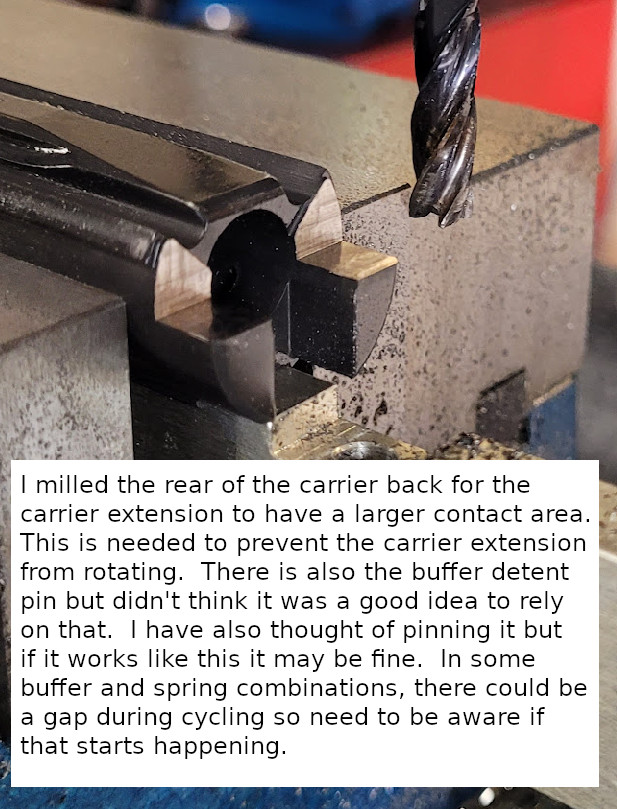

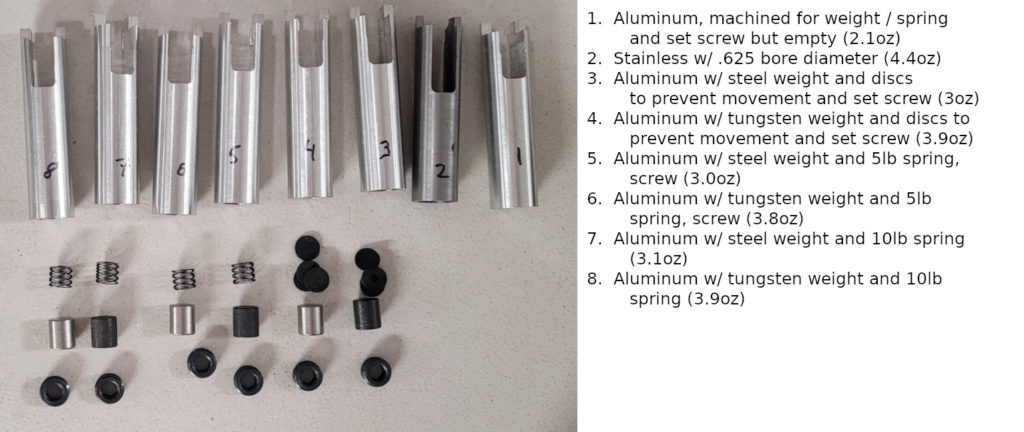

Picture below shows what the bottom of the custom aluminum ‘carrier extension’ looks like. A steel sear trip insert is secured by a bolt that also doubles to prevent the wave spring from going solid height. I bore out the carrier extension to use the same weights used in cheap AR carbine buffers. I prefer using the .6oz steel weight. The 1.4oz Tungsten weight feels too bouncy to me. Note that I typically run full auto suppressed with a short NON-ported barrel. If you run a long barrel, maybe the Tungsten is better. Likewise, as mentioned way down on this page is a BRT ported barrel with a B&T suppressor. Setup is super smooth as he wasn’t consistently getting LRBHO but he was also running 147Gr with an integral. He switched to 124Gr and also removed the steel weight (and spring, set screw) to re-gain LRBHO but still super smooth.

Now that CMMG has released a FE (Fixed Ejector) Banshee, people have asked me if it is still worth it to get a PhaseII.

Below are the main differences.

With the PhaseII, you can remove the rear lug so that you can have an ‘extended stroke’ like I did in 556 documented here: Maximizing BCG Stroke length – “M16 Ultimax” Also documented by one of my customers running in semi only here: https://www.reddit.com/r/AR9/comments/1ik1ceo/the_phaseii_custom_radial_delayed_blowback_by/

The design of my aluminum ‘CE’ allows the use of live mass inside the CE vs dead weight. Like a real MP5 carrier has tungsten powder inside of it to provide more of a dead blow hammer affect.

Details Relevant to both Phase I and Phase II

Phase I – Make the 9mm CMMG Dissent Full auto capable

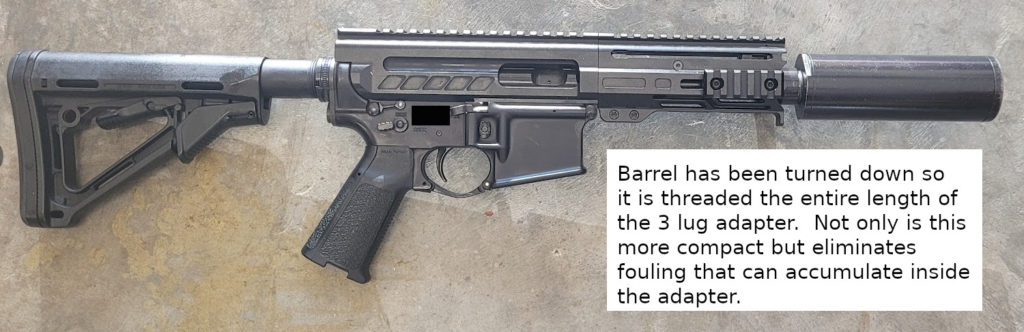

I didn’t like the way the threads were with my choice in suppressor mount so I extended the threads further back.

You can also barely see in the pictures that the Dissent upper is not clearanced for the autosear so I had to mill that out also.

The RB5004 is the smallest and lightest Kynshot buffer intended to be used on .308 platforms but the cyclic rate was too high for my tastes.

Below is similar to my current preferred ‘Banshee’ configuration using the 40SW (#60 bolt) and my custom fixed ejector and yielded almost the same cyclic rate.

Same as above but now using the stronger 556 Tubb spring which typically yields a 30RPM increase in the cyclic rate in my Banshee configuration and I see about the same increase here.

Slightly less reciprocating mass using the RB5005 vs the RB5007 yielding a slightly faster cyclic rate.

Same as above with now the Tubb 556 spring which typically yields a faster cyclic rate. This configuration seemed the smoothest to me.

The RB5000L is the softest Kynshot to compress at around 3.5 lbs and weighs 4.1 oz.

I ran about 300 rounds with no malfunctions on 2/2/24.

I went to a SMG match on 2/4/24 and between myself and couple friends it was at least 700 rounds. It was run in the 604RPM configuration the entire time.

There were 3 malfunctions:

1. I had one round that chambered but didn’t fire and it looks to me like the brass wasn’t fully sized as it has some obvious belling at the bottom (I do use a Lee FCD which usually gets these but who knows).

2. One of my friends had another chambered round that didn’t go off and it was his reloads but he didn’t recover the un-fired round so we don’t know if it had a primer or maybe the primer was inserted upside down / sideways…who knows.

3. I had one event where no round was chambered like the Endomag didn’t feed. I wouldn’t call the guns fault as there was no jam.

So out of all 3 of those malfunctions, I don’t think I can blame any on the gun. Very successful.

I used the aluminum CE which showed no signs of cracking or peening.

Phase II – Modify Dissent Fixed Ejector BCG for standard upper and retain FA capability like Phase I

Carrier Extension Configurations to Test:

The barrel I used for the phase 2 tested is a 7.5″ Stainless Odin Works barrel that I converted to the RDB system mentioned here.

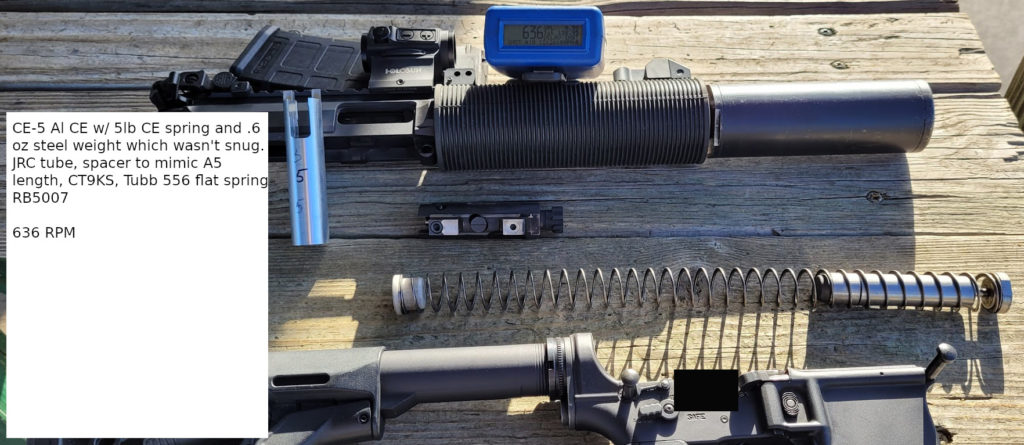

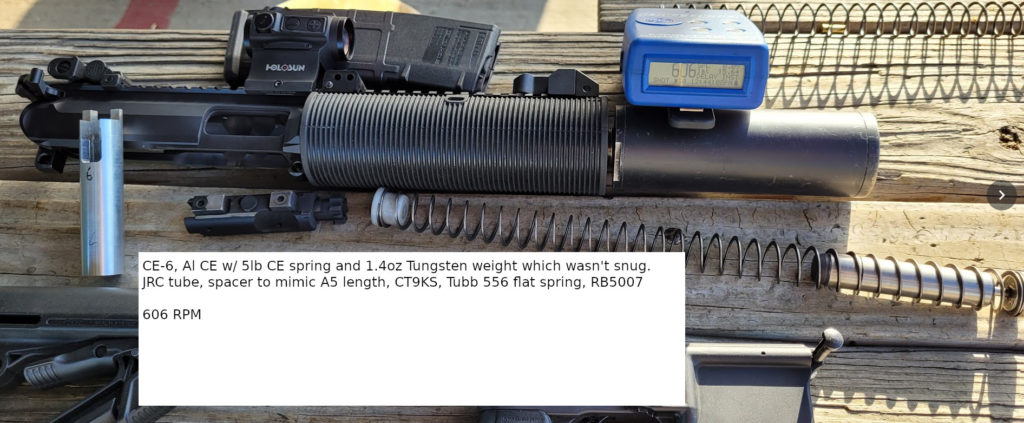

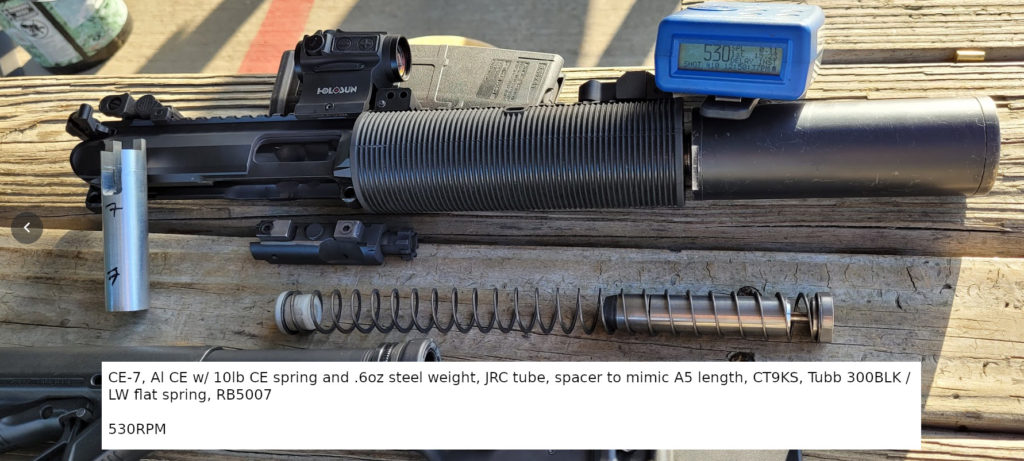

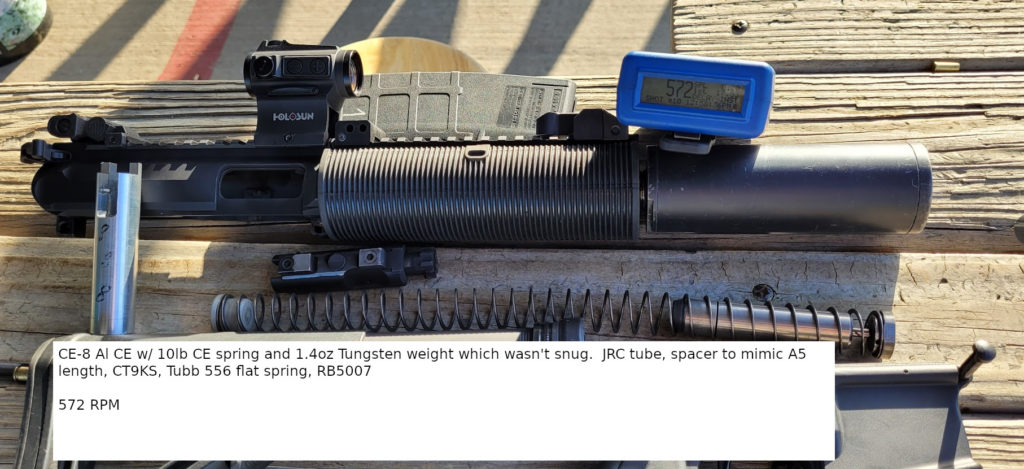

2/24/24 Testing of the above CE’s and the Kynshot RB5007 and either Tubb 300BLK / LW flat spring or the Tubb 556 flat spring.

In the test, I just ran a 10 round mag dump each time to try to get the cyclic rate data. I didn’t pay too much attention to smoothness although I could definitely feel that some were really smooth and some were bouncy relatively speaking.

Below was the only un-suppressed test I did as I am more focused on suppressed usage. The cyclic rate was really nice also so didn’t bother to do more yet.

The first attempt didn’t cycle the first round. Second attempt ran fine.

The first attempt didn’t cycle the first round. Second attempt ran fine.

The first attempt didn’t cycle the first round. Second attempt ran fine.

The first AND second attempt didn’t cycle the first round. Third attempt ran fine.

The first attempt chambered but didn’t fire second round. Second attempt ran fine.

I think below was the smoothest. After completing all the testing. I loaded up a few 30 round mags w/ 1 round in the chamber for the maximum amount of resistance pushing up on the carrier and this setup ran fine.

The first attempt didn’t cycle the first round. Second attempt ran fine.

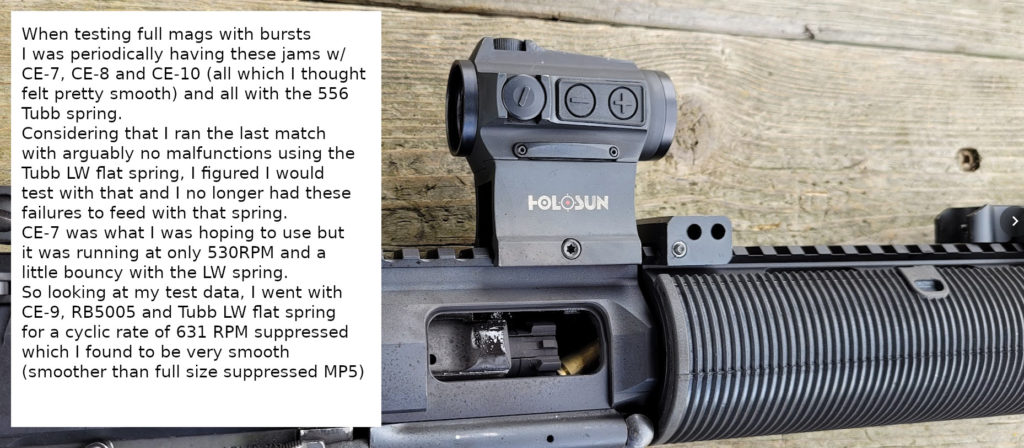

The issue of firing only 1 round happened 5 times with the Tubb 300BLK / LW spring while it only happened twice with the Tubb 556 spring and both times were with the tungsten weight but interestingly it didn’t happen with CE-8 (Tungsten with the 10lb spring). I also felt that the Tubb 300BLK / LW spring did seem a little sluggish stripping rounds but it did work.

What is also interesting is the cyclic rates are consistently lower with the 10lb spring vs the 5lb spring or dead weight.

All data below with RB5007 w/ CT9KS can.

CE-3 (dead steel weight) – 588 / 662 (LW / 556 Spring)

CE-5 (steel weight w/ 5lb spring) – 579 / 636 (LW / 556 Spring)

CE-7 (steel weight w/ 10lb spring) – 530 / 623 (LW / 556 Spring)

CE-7P (steel weight w/ 10lb spring an plug) – NA (LW Spring) – placeholder to test in future

CE-9 (steel weight w/ 15lb spring) – 543 / 671 (LW / 556 Spring) – tested on 3/2/24

CE-9P (steel weight w/ 15lb spring and plug) – 616 / NA (LW / 556 Spring) – tested on 3/11/24

CE-4 (dead Tungsten weight) – 566 / 633 (LW / 556 Spring)

CE-6 (Tungsten weight w/ 5lb spring) – 535 / 606 (LW / 556 Spring)

CE-8 (Tungsten weight w/ 10lb spring) – 502 / 572 (LW / 556 Spring)

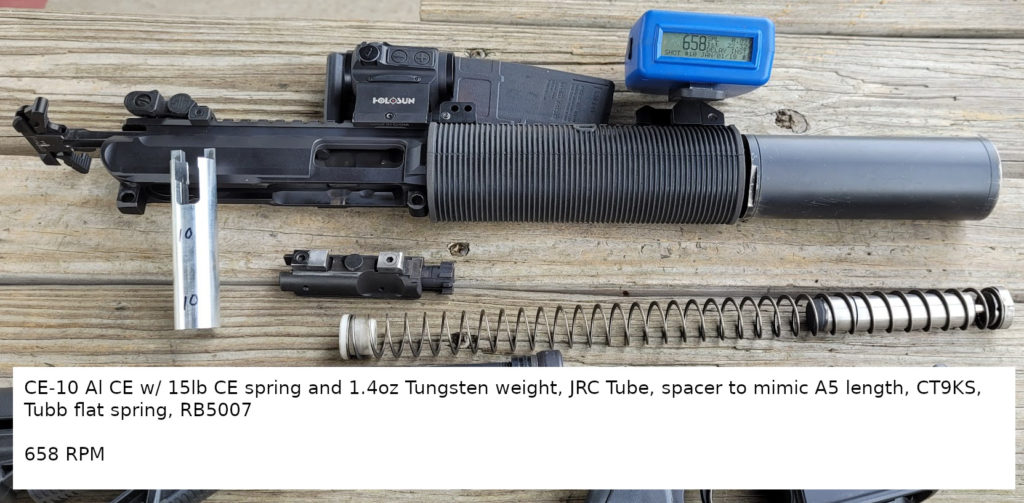

CE-10 (Tungsten weight w/ 15lb spring) – NA / 658 (NA / 556 Spring) – tested on 3/2/24

McMaster also sells a 15lb spring but I never ordered any of those. Ordered later and tested above. It is interesting that going to a 15lb spring increased the cyclic rate considerably over the previous testing.

Based on these results, I plan to repeat all the tests above using the RB5005 but I think I want to limit to only the Tubb 556 spring as I like that it has more force to get the rounds into battery. The RB5005 is 4.7oz while the RB5007 is 5.9oz. I’m hoping that with the appropriate CE, I can stay in the 600’s while also reducing the reciprocating mass.

I placed an order for the 15lb springs and plan on testing two more permutations:

CE-9 (steel weight w/ 15lb spring)

CE-10 (tungsten weight w/ 15lb spring)

Testing 3/2/24

The first attempt didn’t cycle the first round. Second attempt ran fine.

The first attempt didn’t cycle the first round. Second attempt ran fine.

I thought this was pretty smooth.

This was also smooth.

This was even smoother.

This seem a little less smooth than above.

I thought I was going to settle on using CE-8 w/ the Tubb 556 spring, Kynshot RB5005 but was having malfunctions doing full mag testing.

The configuration below is what I am going to try running for a while.

Update – 3/4/24 – I ran the configuration below at the SMG match. All 4 stages and then let several people shoot it after the match. Guessing about 800 rounds with ZERO malfunctions. When compared to my full auto MP5 and both being suppressed, I could keep rounds on target easier with the setup below and it obviously has a much nicer cyclic rate than the MP5. It is a lot of work but I now finally have the configuration I’ve been after for about 20 years. Smoothness of the MP5 with all the benefits of the M16 platform and a better cyclic rate.

Note that the same configuration below was already done above but with the CT9KS suppressor mounted and the cyclic rate was 713RPM vs 564RPM below. That is a huge 149RPM difference. If you look at my old configuration test data, I was getting a 64RPM difference when mounting the MK9K which i don’t think there is much difference in terms of back pressure to the CT9KS. It is interesting to see such a huge difference between suppressed and un-suppressed with this new project. Bear in mind we are now using a 55 degree vs 50 degree bolt and have less reciprocating mass than what is documented here: My 9mm CMMG RDB Setup. The good news is that this system is extremely tune-able. I don’t consider the MK9K or CT9KS to be high back pressure but I may try my Octane 9 on this setup which some have said is high back pressure. I would think that I could mess with the various CE springs in conjunction with a steel or tungsten weight to induce more delay to keep the bolt closed longer to help mitigate any blowback. Which BTW, so far my preferred suppressed configuration does not have much blowback at all…or at least I didn’t notice it and was doing heavy bursts in the match which I ran 100% suppressed.

I have not extensively tested without a suppressor yet. I need to test the setup above using the Tubb 300BLK / LW spring since that is what I’m using for suppressed.

I disassembled the CE to check out how the spring held up and the Tungsten kills them fast. The spring used with the steel weight wasn’t too bad after 800 rounds but not ideal so I made a plug to prevent the spring from going solid height.

Update 3/11/24

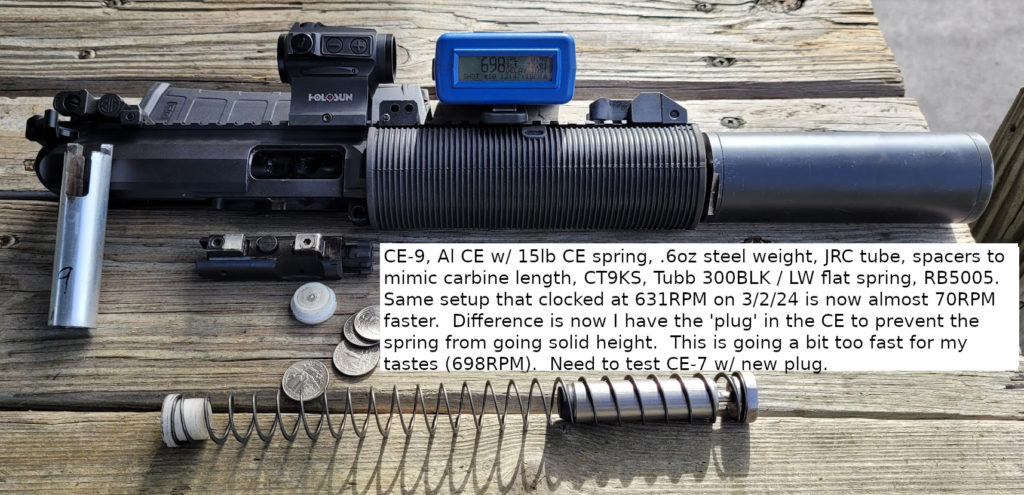

I re-did some of my tests after making the plug that prevents the CE spring from going solid height and now the same configurations are running even faster.

Below is the configuration that ran approximately 800 rounds last weekend at the SMG match with no malfunctions but now is running almost 70RPM faster with the new spring limiting plug. It is considerably harder to pull singles with the Geissele SSF at this rate.

I remembered I never tested the configuration below so I did that as well.

Strange that cyclic rate went up below compared to config above.

RB5005 Testing w/ CT9KS suppressor

CE-1 (Empty Al CE) – 693* / 711 (LW / 556 Spring) *tested on 3/30/24

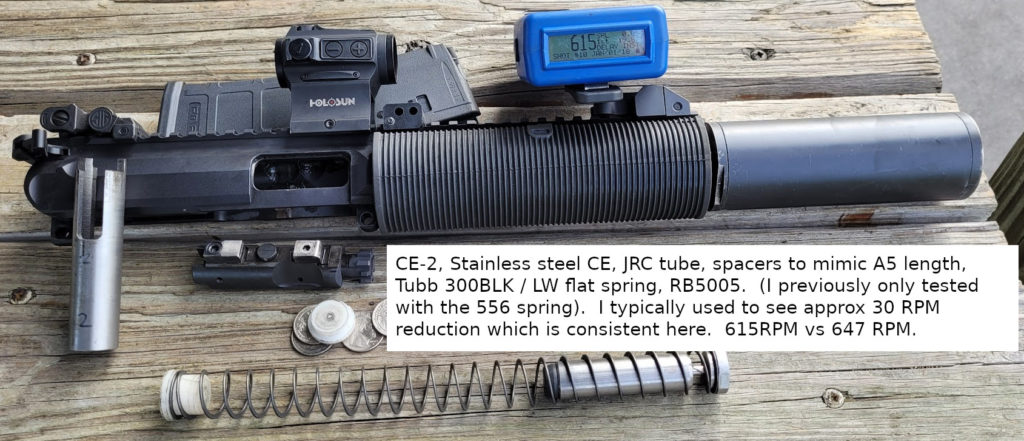

CE-2 (stainless CE) – 615,645* / 647 (LW / 556 Spring) *tested on 3/30/24

CE-7 (steel weight w/ 10lb spring) – NA / 658 (NA / 556 Spring)

CE-7P (steel weight w/ 10lb spring) – 683 – tested on 3/30/24

CE-9 (steel weight w/ 15lb spring) – 631 / 689 (LW / 556 Spring)

CE-9P (steel weight w/ 15lb spring and plug) – 698,682* (LW Spring) *tested on 3/30/24

CE-8 (Tungsten weight w/ 10lb spring) – NA / 652 (NA / 556 Spring)

CE-10 (Tungsten weight w/ 15lb spring) – NA / 653 (NA / 556 Spring)

Unsuppressed Testing RB5007

CE-1 (Empty Al CE) – 611 / 564 (LW / 556 Spring) – results were taken on different days, the LW spring is usually slower, maybe more lube present with LW spring test

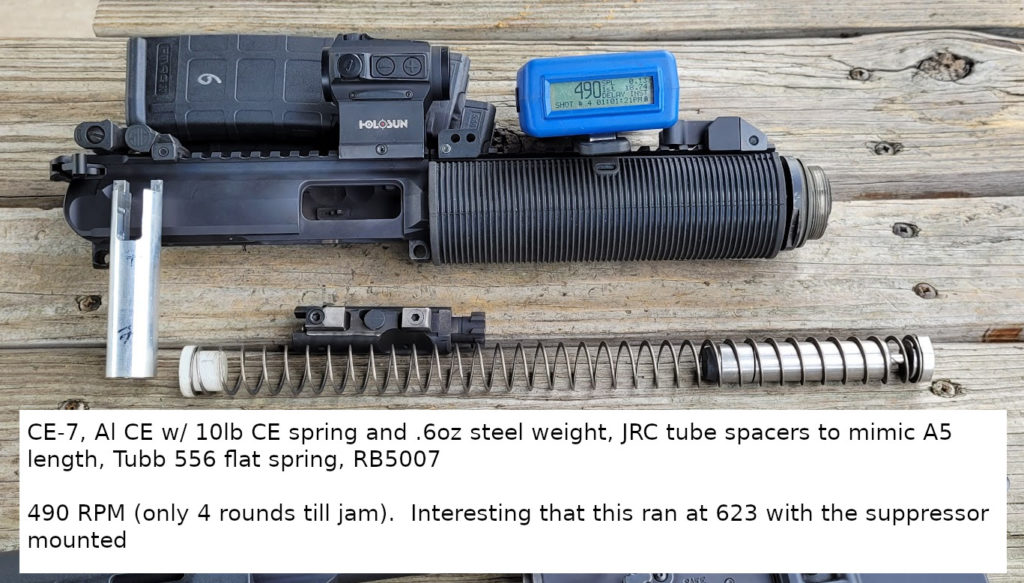

CE-7 (steel weight w/ 10lb spring) – NA / 490 (NA / 556 Spring) – unreliable

Unsuppressed Testing RB5005

CE-1 (Empty Al CE) – 665* / 653 (LW / 556 Spring) *tested on 3/30/24

CE-2 (stainless CE) – 645 / NA (LW / 556 Spring)

CE-9P (steel weight w/ 15lb spring and plug) – 694 (LW Spring)

Upcoming tests – the introduction of the plug to prevent the CE spring from going solid height brought more unexpected results with much higher cyclic rates. I intend to test 1) CE-7 again with the plug (P) and see what I get. In particular, interested to see what happens with CE-7P, RB5005, Tubb 300BLK / LW flat spring and CT9KS. If that doesn’t work out may settle on CE-9P w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (616 RPM) but would like to find a setup using the RB5005 for less reciprocating mass.

Also want to test 2) CE-1 w/ RB5005, Tubb 300BLK / LW flat spring and also test 3) the same setup with the CT9KS.

Update 3/30/24

Was short on time so didn’t do my typically disassembly with pictures after each test and other unsuppressed shooters were at the range which throws off my timer as I set it to be very sensitive when testing suppressed setups. Updates were added in previous results and annotated with the date. Conclusion from the testing: 1) the 7P and 9P tests were almost identical with the plug but the RoF’s are a little too fast for my liking. 2) At this point, I think I need to do some ‘feel’ tests of a few configurations that have the cyclic rates I like.

Suppressed Configurations need to compare

1. CE-9P w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (616 / 621** RPM) 16.3oz reciprocating mass

2. CE-7P w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (639** RPM) 16.3oz reciprocating mass

3. CE-2 – w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (585, 596** RPM) 17.6oz reciprocating mass

4. CE-3 – w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (588, 638* RPM) 16.3oz reciprocating mass

5. CE-2 – w/ RB5005, Tubb 300BLK / LW flat spring and CT9KS (615,645*, 642** RPM *tested on 3/30/24) 16.4oz reciprocating mass

6. CE-3 – w/ RB5005, Tubb 300BLK / LW flat spring and CT9KS (656** RPM) 15.1oz reciprocating mass

**Tested on 4/6/24

Note that while 4 and 5 have almost the same amount of reciprocating mass, the difference is that the mass is in the ‘live / moving’ weight of the buffer body of the longer RB5007 buffer vs the ‘dead’ weight of the stainless carrier extension vs the aluminum carrier extension. You can also see a considerable reduction on the cyclic rate of configuration 4 vs 5 that reflects that mass being in the buffer body vs the dead weight.

Update 4/6/24

As anticipated, I could feel that configuration 4 was smoother than configuration 5 even though the reciprocating mass was almost the same.

Update 4/7/24

Ran the configuration 4 above for all 4 stages of the SMG match full auto and suppressed with the CT9KS. Zero malfunctions during the match. This was the second match run with PhaseII. I was using Endomags. After the match, I was doing some playing around and had some issues where the bolt would close on an empty chamber. So not a jam, just rounds didn’t feed. I pulled the mag and see below. This is obviously a mag problem and not an issue with the gun. I do have 10 of the new MEAN Exomags on pre-order since Thanksgiving of 2023.

I am pretty confident in this configuration at this point and I think it is now safe to start messing with other feeding options. I’m pretty sure it will run great with Glock mags and I do have a CMMG RDB Glock lower but I personally do not like Glock mags for SMGs. I can also go back to the Colt mag setup that I documented here: Mods for CMMG Guard to work with unmodified Colt mags

I am also working on testing a Scorpion mag setup with PhaseII as well.

Update 4/13/24

Did some more comparison testing again and fired some of the same configurations again back to back and re-did some of the cyclic rate tests.

*** Tested 4/13/24

1. CE-9P w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (616 / 621** / 604*** RPM) 16.3oz reciprocating mass

2. CE-7P w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (639**, 638*** RPM) 16.3oz reciprocating mass

4. CE-3 – w/ RB5007, Tubb 300BLK / LW flat spring and CT9KS (588, 638*, 640*** RPM) 16.3oz reciprocating mass

While 2 and 4 have almost identical cyclic rates, I felt that #2 was smoother. It also felt slightly smoother than 1.

I think I am going to run configuration 2 above for a while.

PhaseII with BRD ported barrel and B&T short suppressor

I built a PhaseII for a friend running this setup. He briefly tested it last weekend and it was working fine with his 147Gr reloads. He ran it at the SMG match the next day and it ran fine for the first 2 stages then on the 3rd stage he had some light primer hits and a couple failure to ejects. I thought it was impossible to have failure to ejects with the fixed ejector unless something broke. It looked fine. What I think was happening is that as the gun was getting dirty, the bolt short stroking and not going back far enough for the fixed ejector to kick the brass out which also explains the light hits. In full auto, the hammer has to go back further than in semi since the auto sear has to catch the hammer. Since the bolt was short stroking, the auto sear wasn’t catching the hammer. I told him the ported barrel is really designed to make 115 and 124 Gr subsonic and he shouldn’t be running his 147Gr reloads with that setup. He was running CE-9P, so I later told him to try removing the weight, spring, plug and set screw from the CE and basically run a hollow CE (CE-1) if he wants to run his 147Gr reloads. He did that on 4/13/24 and it appears to have fixed the issue.

Update 5/5/24

Ran the PhaseII at another SMG match. Suppressed using my CT9KS and, 7P CE configuration, LW Tubb flat spring and RB5007. I think it had 1 failure to feed using Endomags. As mentioned before, I think Endomags are like 95% reliable with issues some issues where the rounds will get jumbled up like my picture above, sometimes not feeding fast enough so you end up with an empty chamber and no jam so a FTF wouldn’t be surprising if it was late presenting the round. My attempts to get it to be successful using a re-branding NFA S-9 Scorpion mag lower (XK-9) is still unsuccessful. I think my CMMG Glock lower would run 100% but I really like using an M16 lower and not go back to using a RDIAS for this setup so still waiting on the MEAN Exomags to be released to try out….but I may just change my mind and go back to the Glock lower too.

So very pleased with it’s performance. I have a few friends that I built these for and they all appear to be running great as well. Some guys want to run only un-suppressed . The suppressed guys are all running different cans than I am as well so varying levels of backpressure / fouling. Will have some interesting data points in the future. I delivered one unit to a friend and told him he needs to use the LW Tubb flat spring or equivalent or he will have FTF’s, he had a black coated flat spring that he thinks was from Midway and is longer than the LW Tubb and as I anticipated, had FTF’s. He hastily cut it down and it performed better for the match but still occasionally had FTF’s. It is unclear if it could be the Endomags or spring rate of his spring. He is going to try switching to a Glock lower to see how that runs.

Update 5/13/24

Ran the PhaseII at another match and it still continues to run very well. I also built two more uppers as pictured below for some local competitor friends and one of them ran 100% for all six stages of the match. He only likes to shoot unsuppressed. He was running 115Gr Winchester with Endomags.

Update 6/2/24

I am still tinkering with getting Scorpion mags working as documented here: https://c3junkie.com/?page_id=2102 but I don’t have LRBHO working yet. So decided to get the parts together to run unmodified Colt mags instead. I did this back around 2018 but back then CMMG didn’t offer a kit to do this so I bought their kit and made modifications which are working out VERY well. https://c3junkie.com/?page_id=374 I bought several thousand blemished 147Gr FLAT nose projectiles from American Reloading thinking it would function in at least some mag iteration for one of my PhaseII builds. Turns out I cannot reliably run those bullets in Glock, Endomags or even the curved Scorpion mags. They all jam but they actually feed very well with Colt mags which are obviously straight.

I ran probably around 500 rounds through my Phase II w/ the Colt mags and did have 1 failure to feed with the FLAT nose bullets which I’m pretty happy that it has run so well. it is also running with Suomi converted drums for the Colt 9mm setup which interestingly I could never get to run reliably with my straight blowback configurations.

Another competitor also showed up with a Phase II I built for him that he ran unsuppressed with 100% reliability for the entire match.

Update 7/11/24

Myself and a couple friends were having issues where the corners of the RDIAS trips are worn and interface the worn corners of the aluminum CE. So I modified the aluminum CE’s to accept a steel insert. I used a bolt to secure the steel insert which serve dual function to also prevent the spring from going solid height eliminating the need to machine a separate plug. I had one CE which happens to have a thinner wall than the other ones I made so there is more room inside to use a longer spring. Doing so yielded interesting results as pictured below with one of the slowest cyclic rates I have seen with a suppressor mounted and the steel buffer weight. Note the Warthog spring is stronger than the Tubb LW / 300BLK spring which typically has a higher cyclic rate. This configuration has a low reciprocating mass and still very smooth.

The Neverwear ‘Warthog’ flat spring’s power is between the Tubb LW and Tubb 556 flat spring and I have found it to work with all the feeding options pictured below. While the LW spring would work for the Endomags, it wasn’t strong enough for the Colt or Scorpion mags for example and if you used the Tubb 556 spring with the Endomags it was too strong and would sometimes have failures to feed. I have also found the Warthog spring to work fine with the RB5007 / A5 in my 556 setups as well.

Thoughts / Observations

- The 9mm Dissent bolt uses a 55 degree bolt while the 9mm Banshee uses a 50 degree and the .40SW Banshee uses a 60 degree bolt. I think they did that since you have less reciprocating mass with the Dissent since it is bufferless and consider the end users are most likely going to run suppressed and un-suppressed. This worked out great for me since I intended to run 99% suppressed and wanted an increased delay over the 9mm CMMG Banshee bolt.

- ‘Sustainability’ of the platform. There is not much to wear out on a straight blowback setup. That is not the case with a delayed system. Take the MP5 for example, the extractor springs are known to wear out but new designs have appeared to address that but you still have wear on the locking piece and rollers. Extremely high round counts you will have to swap trunions and in some cases, the receivers may have fatigued beyond repair. While the CMMG is really just the extension and bolt that handles the delay. Considering you can readily buy or make your own barrels and the BCG is available from CMMG, I think this platform is very sustainable today. So out of the box the impulse isn’t as smooth as an MP5 but with the tuning I’ve done here I think it actually exceeds the MP5 in that it is just as smooth but a better cyclic rate. I have probably around 50K through my custom SS CMMG barrel and it still works fine. I think I may have to try to get some pictures of what the lugs look like. However, if I have to swap extensions or even replace barrels it isn’t that big of a deal and worth it to me.

- Reciprocating mass. If you have read through all of this, hopefully you can see the dramatic difference of ‘live’ mass vs ‘dead’ mass. ‘Live’ mass moves upon the initial recoil impulse and moves forward to counteract bolt bounce on the forward stroke. My goal was to reduce the reciprocating mass as much as possible. If you look at the first test I did with the RB5004 which is one of the lightest Kynshot hydraulic buffers, it was bouncy and had a high cyclic rate. I then focused on the RB5005 (which I tried with my old CMMG ‘Guard / Banshee’ setup). I ended up going back to the RB5007 just like I did with the old setup. Not only for cyclic rate reduction but for the smoothness of the recoil impulse. While the RB5007 is the heaviest of the 3, almost all of the mass is ‘live’. If you look at the high speed videos I have done, you can see that the body of the Kynshot moves forward on the initial recoil impulse or you can say that the mass is stationary as the BCG is moving backwards. Either way, the additional mass helps to soak up recoil. On the forward stroke it helps to eliminate bolt bounce. The negative is that the gun does shift some when going into battery which is what I have been trying to minimize. Firing this configuration with 1 round in the mag that has an operational LRBHO follower is amazing to feel almost no recoil with no bolt ‘lurch’ going forward. While I would like to get the mass down further like MP5 weight (9.3oz), I don’t see a way to do that yet. However, note that one of the reasons to do this build was to have a slower cyclic rate than what is possible with an MP5 and retain smoothness which this has achieved. So while this configuration is around 7oz heavier than the MP5 BCG, most of the additional mass is ‘live’ mass. I don’t know if the analogy is valid but I sometimes think of the Nielson device / ‘booster’ used on suppressed pistols. The booster mechanism adds some mass to a suppressor that is already too heavy to cycle on the pistol but in result makes the suppressor ‘live’ mass. So I don’t think looking at the mass as a number is that simple. It depends on how that mass is used.