Here is a link to an archived thread on AR15.com dated 7/21/2020 https://www.ar15.com/forums/ar-15/New-NFA-S-9-Lower–Scorpion-mags—Pics–review-and-build-in-progress-with-CMMG-RDB/15-754694/

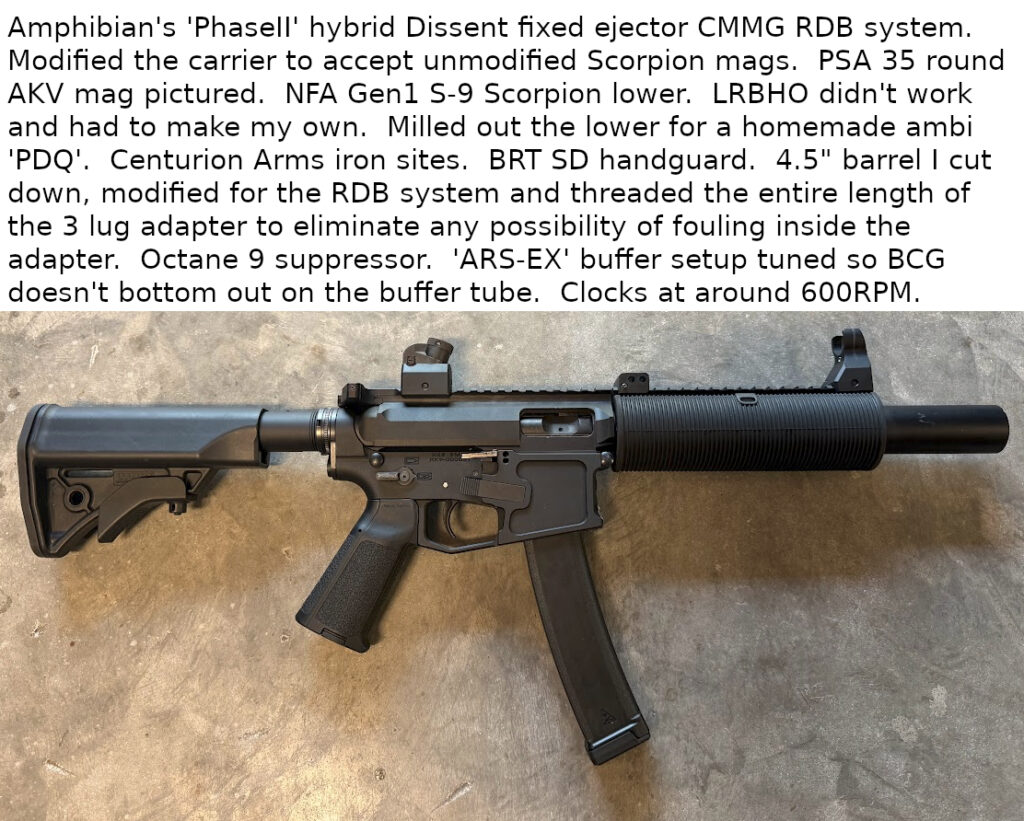

The poster in that thread was using an NFA (New Frontier Armory S9) lower that is designed for straight blowback and unmodified Scorpion mags. I haven’t seen them for sale and reached out to NFA in March of 2024 and was told that they were discontinued but plan on re-releasing a Gen2 version towards the end of 2024. Some may say why not wait for the Gen2 to come out, the thing is I don’t know if the Gen2 will make it more difficult for me to adapt to the CMMG RDB system so might as well get this setup now since it should be straightforward but it wasn’t as you can see from my documentation.

I saw on Gunbroker https://www.gunbroker.com/item/1049049499 was selling their ‘XK9’ Scorpion mag lower which is a rebranded NFA S9 lower. Currently as of 5/2024 they have 10+ in stock for $179.

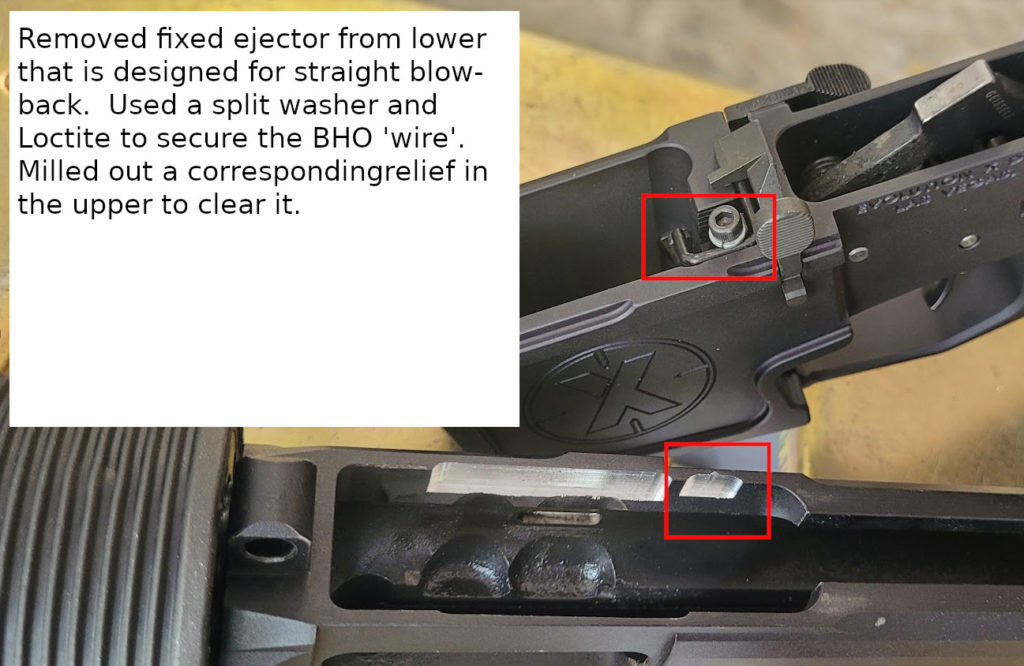

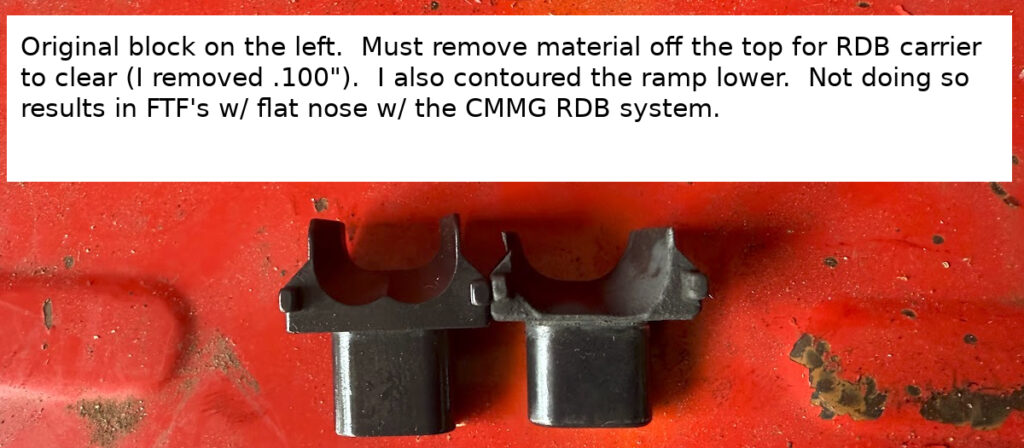

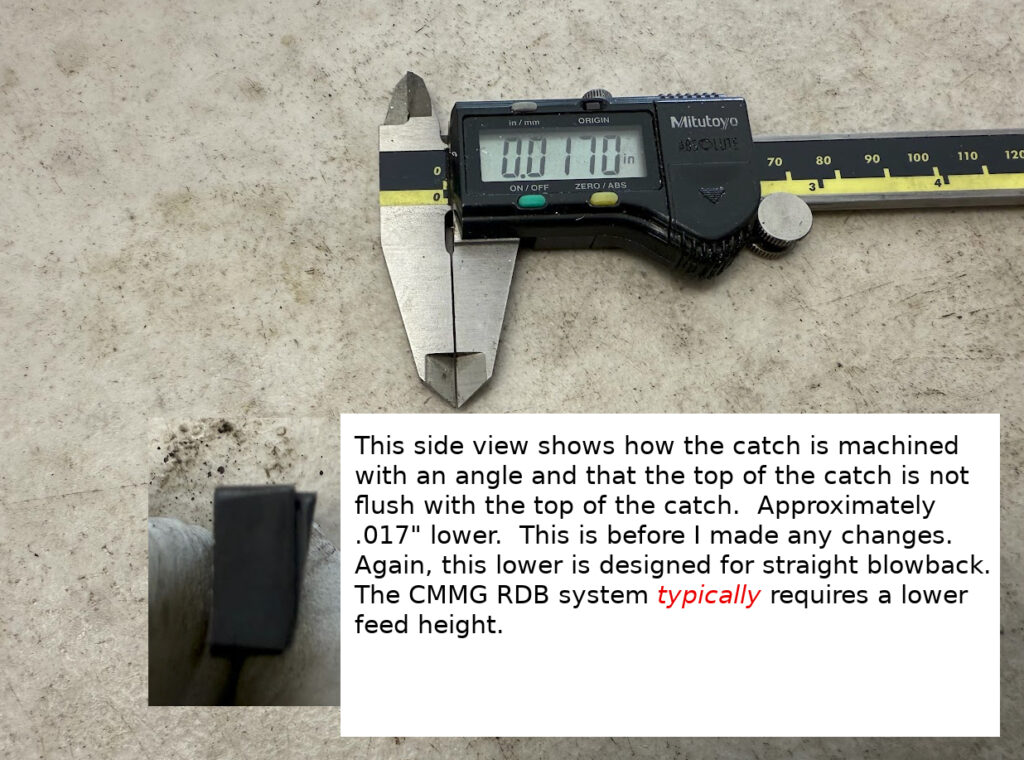

Again, this lower is designed for straight blowback not the CMMG RDB system. The CMMG RDB system typically requires a lower feed height than straight blowback. Colt mags definitely need to be lowered to work the the CMMG RDB system. Some Glock lowers work with both straight blowback and the CMMG RDB (but you do need to remove the ejector from the lower). The PSA Glock lower is such an example. Since someone already got the CMMG RDB to work with the S9 lower, I figured this would be an easy project since he already did all the leg work. However, as you will see here I had to do a lot more work to get mine to be reliable.

As a side note, I have two friends that also bought this lower and they couldn’t get it to work with straight blowback which it is designed for. Stating it is feeding too low which again is what you typically need for the CMMG RDB system.

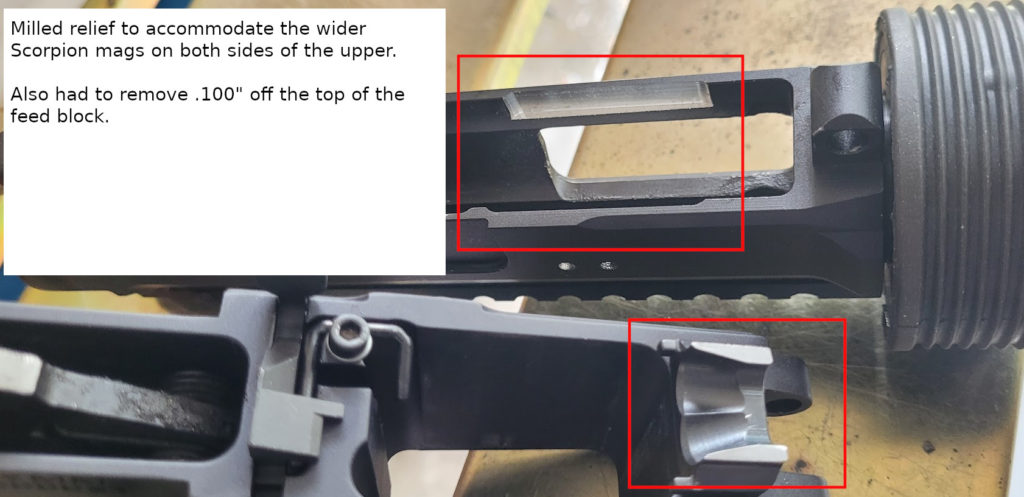

This requires using an upper that has been clearanced for the wider Scorpion mags. I mentioned on the thread above that you could use a PSA KS47 upper and I know someone posted on another thread that he did just that with no issues.

In the thread, the poster mentioned having great luck with the Manticore Arms designed Scorpion mags that use the steel feed lips sold by Prepper Gun Shop. Using these mags, no bolt or carrier mods are required. So I ordered 10 of these mags and opened the plastic wrap on 4 of them. All 4 of them are unreliable for me. Just stripping the rounds off a fully loaded mag with my thumb was bad. The next round would sometimes just sit there or slowly move up. Clearly won’t work for live fire. I didn’t realize this till after trying to shoot them which was a failure. I reached out to Prepper Gun Shop and was told there is a lifetime warranty but they would refund me only on the ones I didn’t break the plastic bag on as well as charge me a 10% re-stocking fee which I did for the six mags. I am stuck with the 4 lemons and am hoping that maybe when they get a batch of smoke or whatever I can swap them as mine are clear but in the thread his were clear too so I don’t know.

Picture below is after I had clearanced my ‘Phase II’ upper for the Manticore Arms mags but made no bolt or carrier mods.

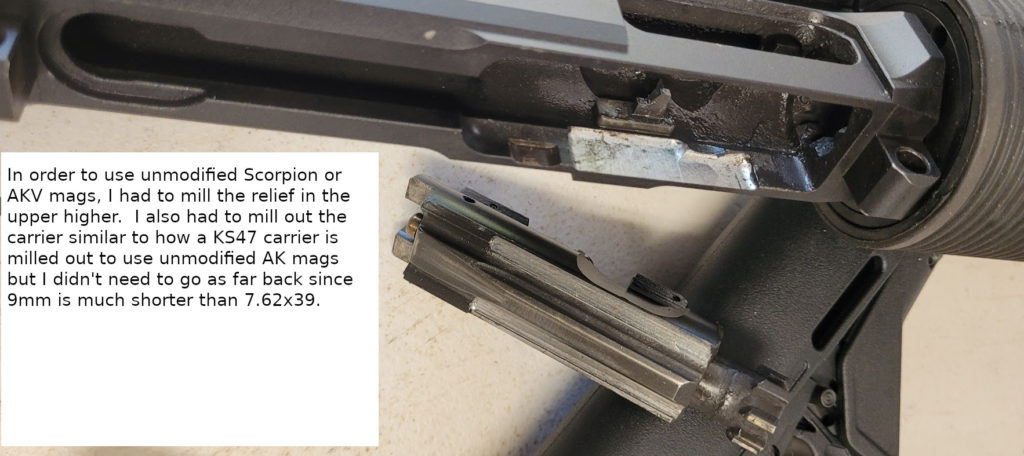

After the failure with the PGS / Manticore mags, I didn’t want to give up and figured to try making the mods to use factory Scorpion or PSA AKV mags which do have a great reputation. Refer to my page for carrier mods to use unmodified AK mags here: https://c3junkie.com/?page_id=185 I used a PSA KS47 carrier to make sure it would clear factory Scorpion mags as well as PSA AKV mags.

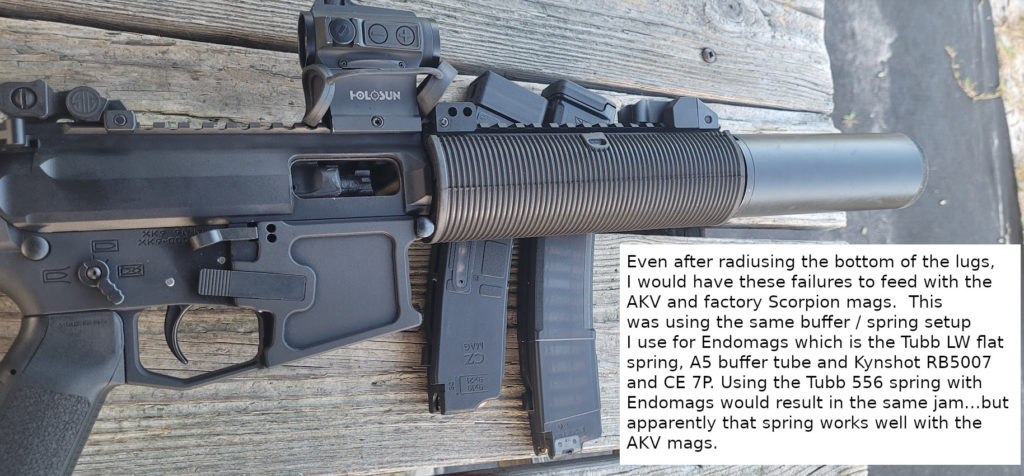

You can barely see in the top right of the picture below that the carrier has been milled out to clear the AKV and factory Scorpion mags. It is dirty but I had mill both the ‘canal’ area underside the carrier as well as the ‘ski’ area.

I thought that was all that needed to be done but under live fire or even dry cycling the lugs on the bottom of the bolt would get hung up on the case mouth and rob a lot of energy on the rearward stroke causing malfunctions. I have run into this before with my 5.45×39 setup and radiused the bottom lugs of some bolts to fix that. However, with the RDB system the rear of the lugs need to interface with the extension lugs to control the delay. On this particular bolt I didn’t see much wear in that area so took a chance and lightly radiused the two bottom lugs.

Additional machining operations required to run unmodified AKV or Factory Scorpion mags.

Below are the results after radiusing the bottom two bolt lugs.

Before I thought about going back the 556 Tubb flat spring, I also tested using CE-10P (15lb spring, plug and Tungsten weight). Using that got it to be reliable and eliminate the FTF’s but I felt the tungsten weight made the gun a little bouncy so going to the 556 Tubb spring seems to be the better way to go.

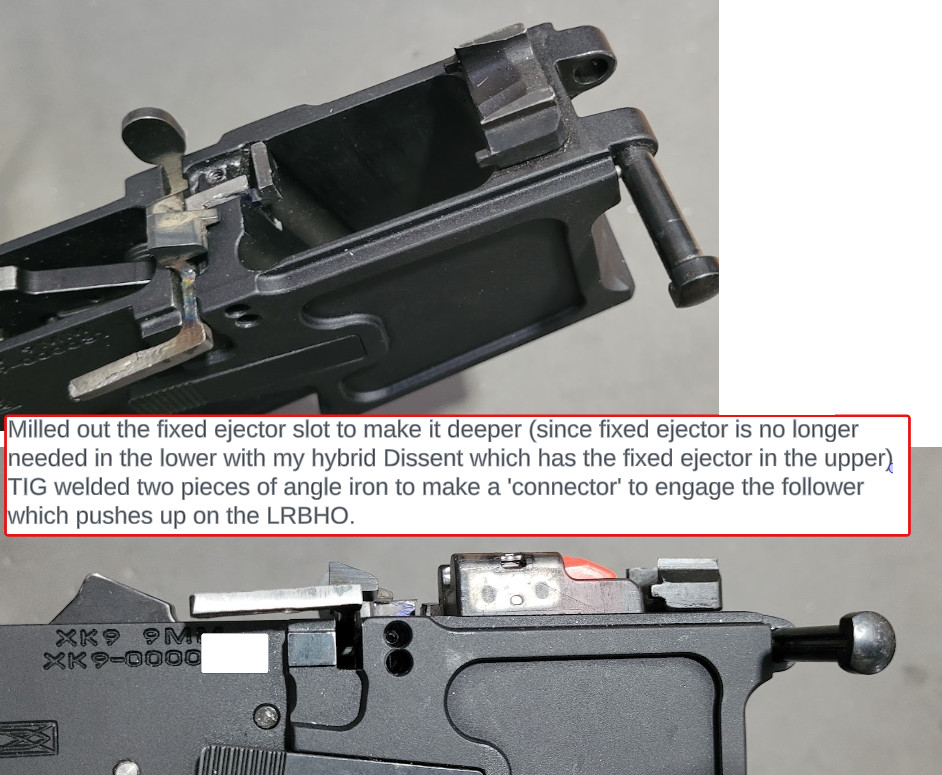

I am currently working on LRBHO functionality as it wasn’t lifting the BHO high enough to catch the bolt. I called one of my friends using this lower for straight blowback and it doesn’t work for him either. I tried bending the wire but I ended up cracking it trying to bend it enough to work. So I will be working on that next.

Update 7/6/2024

LRBHO is working now. Took a long time but I took two pieces of angle iron and TIG welded them so it looks like an ‘S’. Then milled a slot in it so that the set screw that was previously holding the straight blowback fixed ejector in the lower is now a retention pin for the LRBHO ‘connector’ I made. If I used both screws it was binding. It seems to be working fine with one screw. I also cut a few coils off the BHO detent spring to make it easier for it to work. Another option is to get a lightened bolt catch spring like this on from Catch22: https://www.brownells.com/gun-parts/rifle-parts/rifle-bolt-parts/lightened-bolt-catch-spring/

Rather than use the ejector set screw, I ordered couple of these from NFA: https://www.newfrontierarmory.com/bolt-catch-threaded-pin-mag-catch-pin-c4-c9-c5-c45-c10 so that the ‘connector’ would have a smooth surface to interface with.

Configuration on the bottom is how I am running it now. Either with the Ca$h9k or a Griffin Armament Bushwhacker36.

Update 8/2024

I had issues with the HK fluted barrel and now swapped out with a barrel with a standard chamber.

Update 9/15/2024

Having FTF again so went back to the 7.5″ barrel that was working before and it still does it. I also noticed that if I load 1 round in the chamber and then load a full 35round AKV mag, it is too much resistance and will result in the bolt not going back far enough for the ejector to kick the brass out. This is with CE9P.

I put two strips of duct tape as pictured below and not have FTF’s anymore but did this in conjunction with going back to the Tubb 556 flat spring and had to use an empty CE for it to function with a round the chamber and fully loaded 35 round mag inserted.

All this testing was done with the 7.5″ barrel. I also noticed that if I removed my CT9KS it wouldn’t consistently go back far enough to get LRBHO. The Cash9K consistently locked the bolt back as to be expected since it has higher back pressure than my CT9KS.

I went back to my 4.5″ barrel and re-tested. I can’t use the CT9KS with the 4.5″ barrel and BRT SD handguard so I tried with the Cash9k and the Bushwhacker 36. With the shorter barrel and the Cash9k, it was sporadic in reliably chambering the first round on a full 35 round with 1 round in the chamber. It was 100% reliable with the Bushwhacker 36 which I think has higher back pressure than the Cash9k but is also quieter than the Cash9k. This was confirmed with my 147Gr Titegroup load, Dater’s load and also my 155Gr VVN340 loads.

Update 3/2025

I am still having occasional FTF’s.

Still having occasional FTF’s.

Update 9/2025

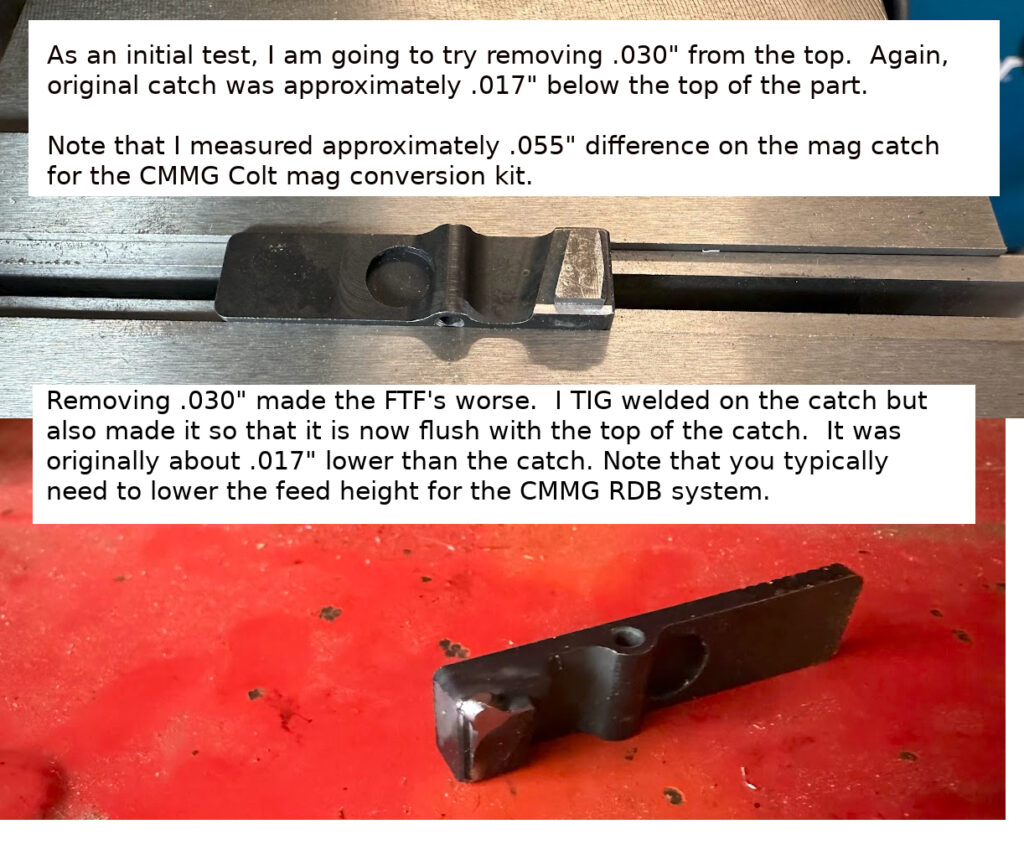

Been sometime I’ve messed with this setup but I happened to finally get some Centurion Arms HK style sites so decided to re-visit it again. It is currently running pretty good with the modified feed ramp that I had to lower, unmodified mag catch and a few strips of duct tape in the front to get the proper alignment. If I remove the duct tape, even JRN won’t feed when dropping the bolt. It won’t feed flat nose bullets.