As many of you know I do a lot of testing and my information is scattered all over this site as well as many posts online. Since I am always tweaking with my CMMG RDB setup, I thought I would setup this page and try to to keep it up to date with what I’m working on.

For some background, I am always trying to reduce the reciprocating mass but still maintaining a slow cyclic rate (preferably around 600RPM is what I target). At that rate, I can pull singles and doubles at will.

The CMMG RDB was introduced as the ‘Guard’ in 2017 and was initially in .45ACP. Soon after they released it in 9mm and I was an early adopter. The first barrel I got from them had excessive head spacing and was breaking cam pins, firing pins, extractor pins etc….this was also killing ejector springs very quickly. This is all documented here: CMMG RDB Ejector Spring Issues

However, as discussed here: 9mm M16 SMG Options, I felt there was no good alternative for my criteria so I went through the trouble of doing a custom fixed ejector as documented here: This is my previous 9mm CMMG RDB (Guard / Banshee) configuration that I no longer run. I currently run my 9mm fixed ejector ‘hybrid’ CMMG Dissent.

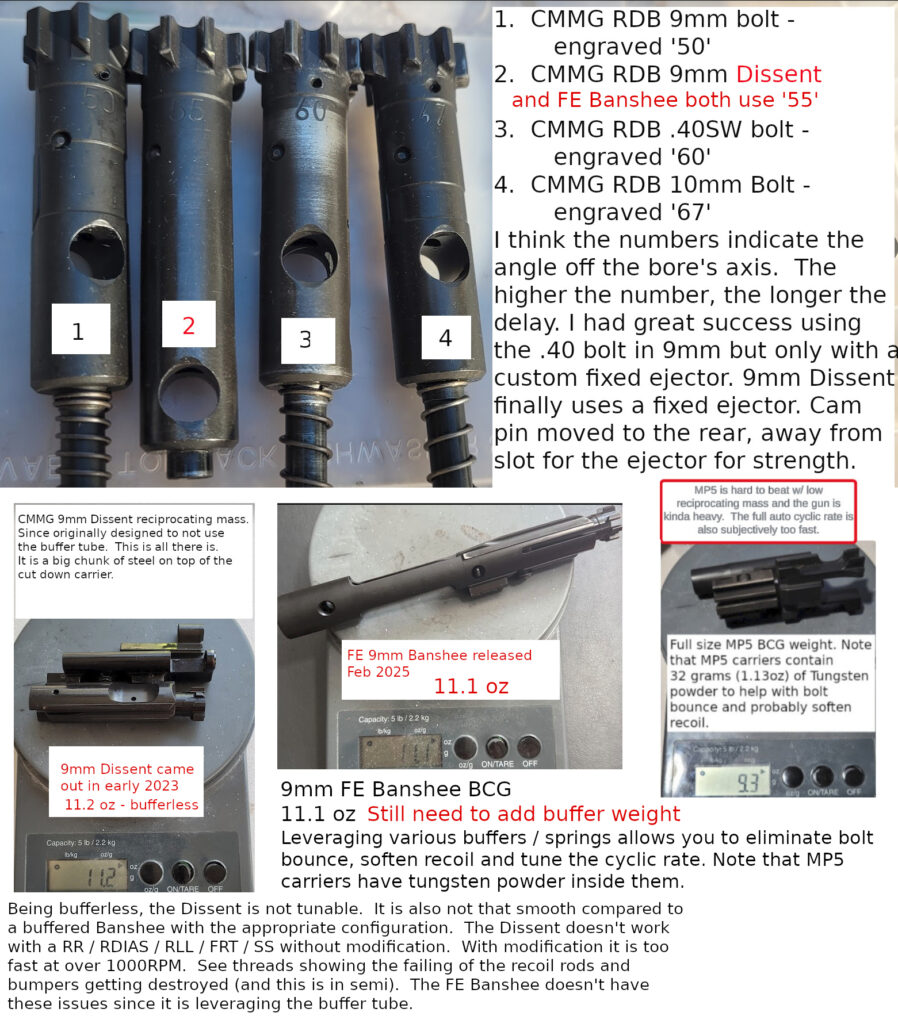

Below is a high speed video of my old setup below that I was running till around 2023. I felt it was as good as it was going to get but still felt that the reciprocating mass was still too high and you can see the gun shifting forward when the BCG goes into battery. Notice that I mention using a 40SW CMMG bolt which is a 60 degree bolt and would only function with a suppressor mounted. The original 9mm Guard actually came with a 45 degree bolt and they later changed to a 50 degree bolt and also later engraved the bolts 50.

CMMG released the 9mm Dissent in early 2023 but I was not interested since it was bufferless (not that smooth as I demonstrated with high speed video), it was not full auto capable and I love the buffer tube so I can leverage various buffers and springs to slow the cyclic rate down and soften the recoil impulse. However the 9mm Dissent finally used a fixed ejector which eliminated the issue of ejector springs failing on the original 9mm Banshee’s. The 9mm Dissent being bufferless came with a 55 degree bolt which makes sense since there is no buffer the reciprocating mass is only 11.2 oz.

So again, I resorted to doing custom work to get what I want and made what I call the PhaseI (modify the side charging Dissent to use the buffer tube again) and then the PhaseII (use the buffer tube but traditional rear charging). Since I had to make my own ‘carrier extension’. I was able to use lighter aluminum which worked out to about 9oz hollow or around 10oz if I wanted to use a spring loaded weight inside the custom ‘CE’ which I think increases the delay. This is all documented here: Ultimate Full Auto CMMG RDB Fixed Ejector Project (hybrid Dissent 9mm). This was all a lot of work but worked great when combined with my preferred buffer, buffer tube and spring as documented here: ‘ARS’ – Amphibian Recoil System and ‘ARS-EX’ Amphibian Recoil System Extended. My lighter BCG also helped for unsuppressed use with the higher 55 degree bolt. Some customers running ported barrels also would run my custom CE hollow to get the BCG down to 9oz for less reciprocating mass.

Then in February 2025, CMMG released their FE (Fixed Ejector) Banshee line in 9mm and .45ACP. They used the SAME 55 degree bolt that is used in the Dissent. I think they did this to obviously not have to make two different bolts. Knowing that my 60 degree bolt would only function suppressed. I thought that in some cases the 55 degree FE Banshee bolt may be too much for some situations like people using weak ammo and no suppressor or ported barrel and too heavy of a buffer and there have been several threads posted with this exact issue.

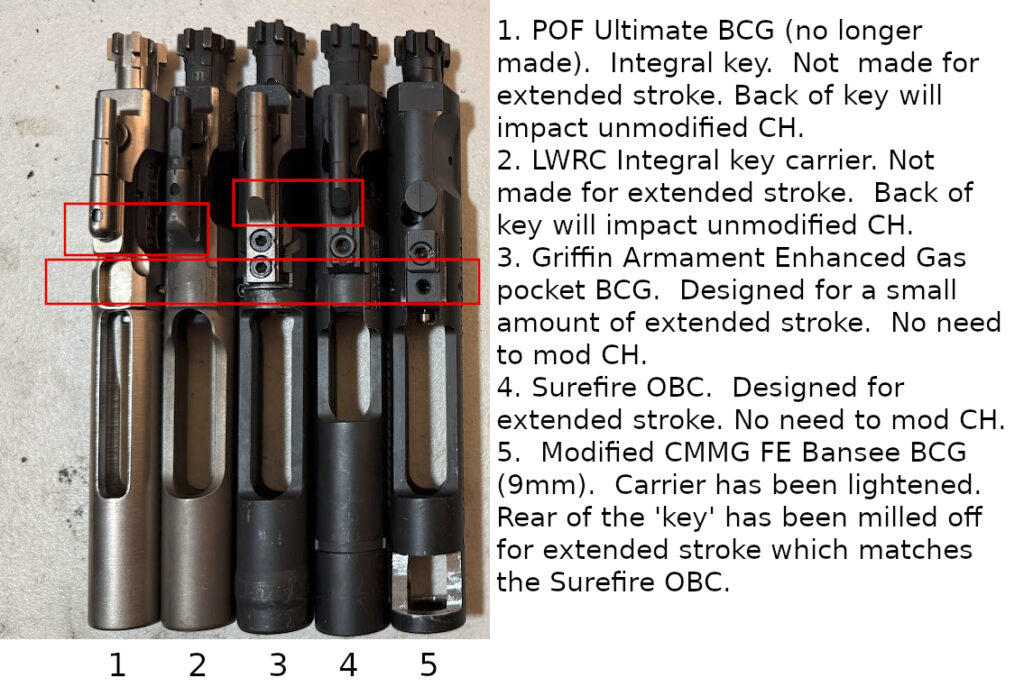

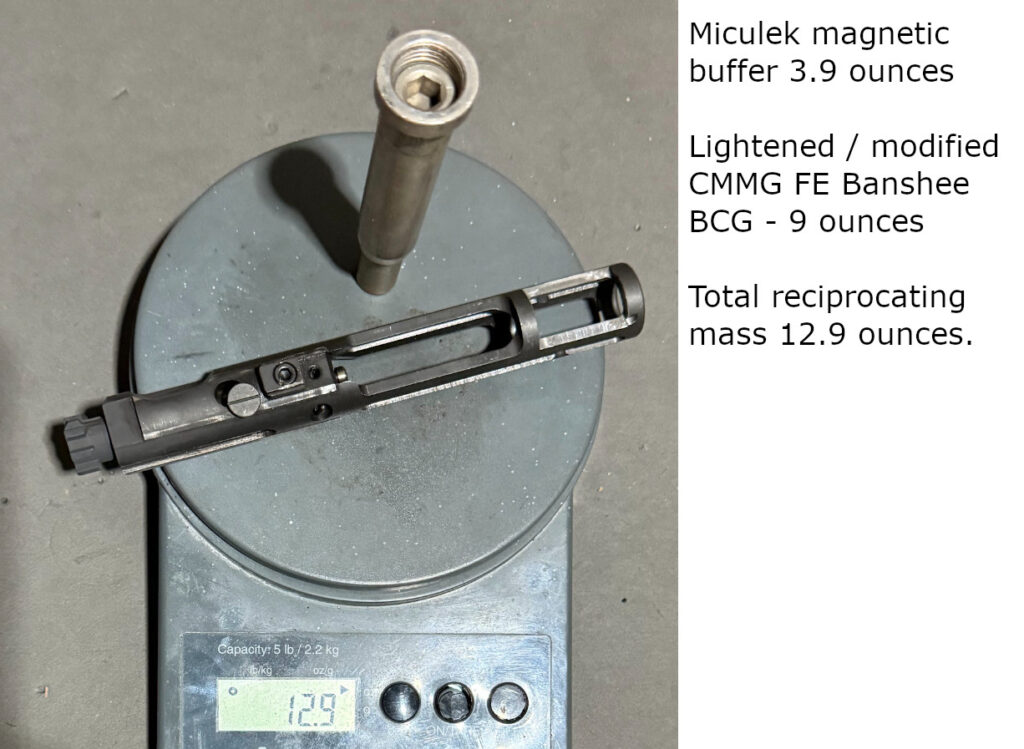

Picture below shows a FE Banshee BCG that I have lightened and also notice that I milled off half of the ‘key’ to allow for additional stroke. Picture below shows that my modified FE Banshee BCG matches the Surefire OBC in regards to the key area to allow for the additional stroke.

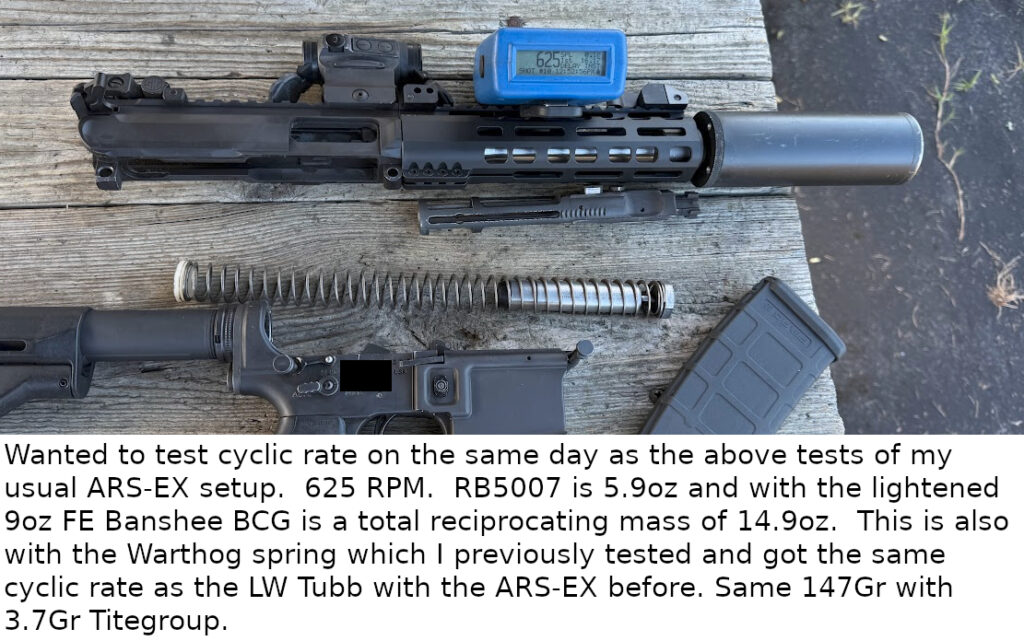

Lightening the carrier and modifying the key allowed me to match my custom PhaseII setup of a 9oz BCG but I wouldn’t have the ability to further delay the action with spring loaded weight in the carrier. I have been a fan of the Kynshot hydraulic buffers for a long time and in particular the RB5007 which is about 5lbs to compress vs the RB5015HD which is about 10lbs to compress. High speed videos show that the body of the buffer moves slightly forward on the initial recoil impulse which spreads that impulse over time making for a smoother recoil impulse…..however the RB5007 is 5.9 ounces and I would like less reciprocating mass but I also want my cyclic rate to be around 600RPM.

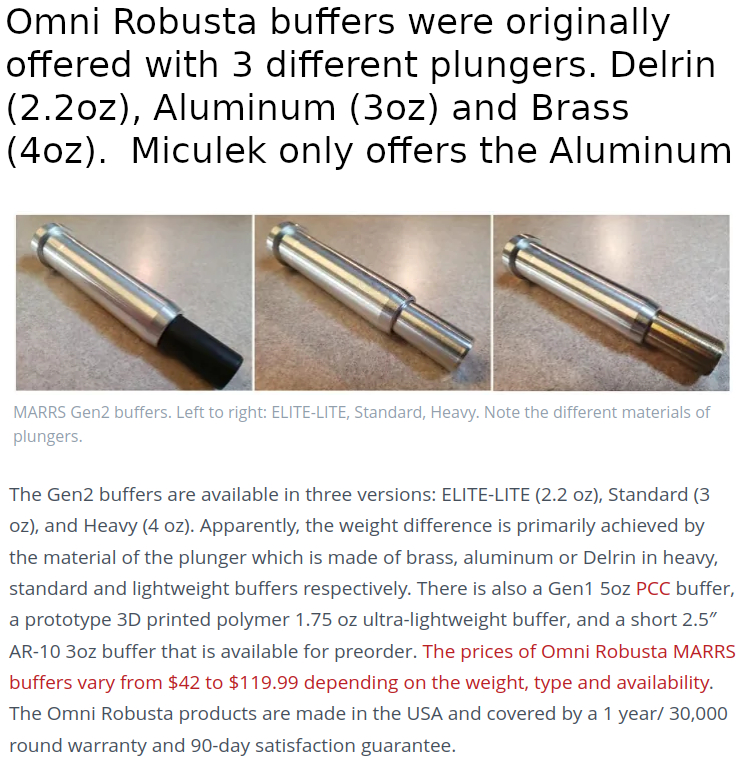

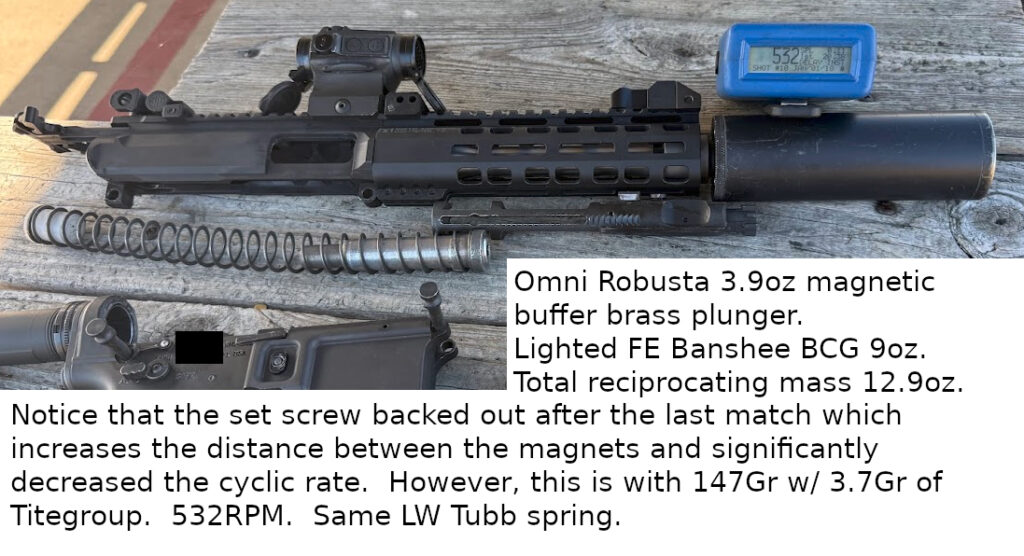

I remembered that I have an Omni Robusta magnetic buffer that wasn’t on the market very long before Jerry Miculek bought the patent. However, I do recall that I briefly tested it in full auto and it didn’t work but I think it was in 5.56 and I can’t remember what all the parameters were so I figured I would test it again for the 9mm RDB.

As you can see in my picture below I have the brass one.

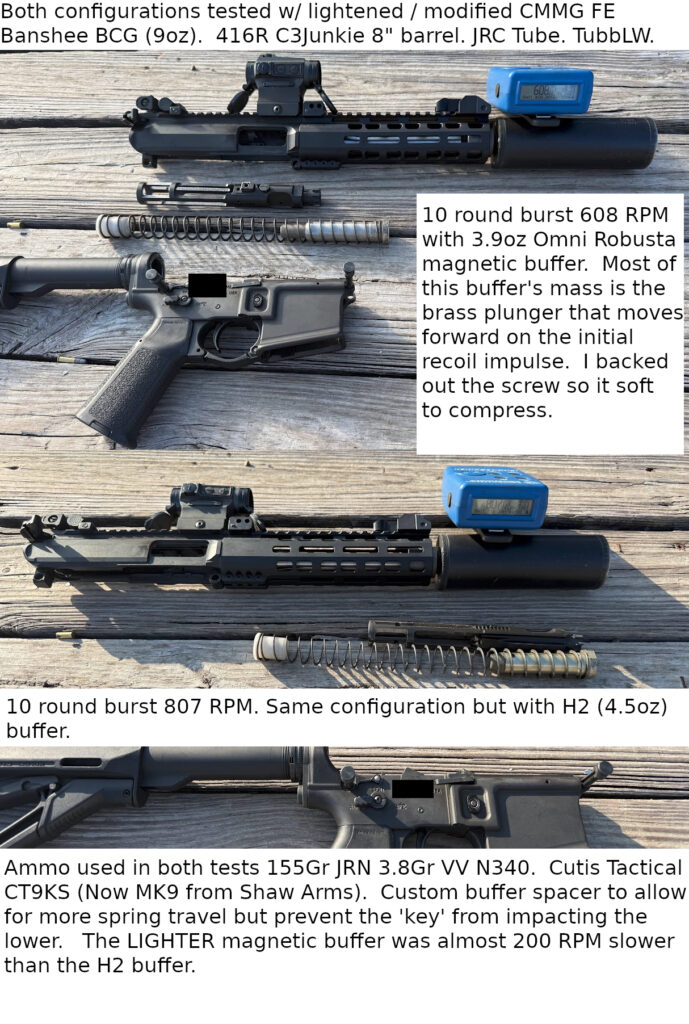

Below is my initial test. Note that I’m still using my longer JRC buffer tube and just used whatever spacers I had on hand so the key wouldn’t hit the lower. Also using the Warthhog flat spring. 673RPM is a tad fast.

Below is a video of the setup above:

I made a custom spacer to be used in conjunction with the JRC tube so that the spring could go almost the entire length and stop the key from hitting the lower. It was my hopes that the weaker Tubb LW spring would get me in the low 600’s and this is about perfect. I also backed off the set screw some so less force is required for the brass plunger to move forward.

12-7-2025

I ran around 400 rounds through this setup today with zero malfunctions. I was using Endomags and 40 round Exomags. I loaded the Endomags to max 30 round capacity and the 40 rounders to max 40 rounds as well. In several cases, I would have a live round in the chamber and insert the full mag. I was totally anticipating that the weaker Tubb LW spring combined with the long JRC tube and my spacer allowing the spring to go almost the entire length that it would fail to strip a round off the full mags. However, that did not happen one time. It was 100%. I also never stopped to clean. I think that the design of this buffer where a large majority of it’s mass is the brass plunger provides the inertia necessary to help chamber the round. I did add a few drops of Mobil 1 0/40W at the half way point though.

The video below shows a stage where you engage the white round steel plate with 1 round. Small rectangle with 2 rounds. Square with 3 rounds. Big rectangle with 4 rounds. Selector is set to full auto at all times.

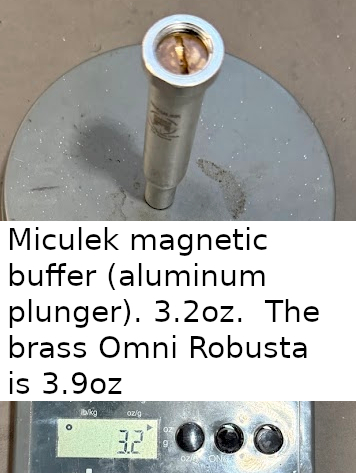

I ordered the Miculek buffer for testing which should be 3oz. I suspect it will have a higher cyclic rate but considering that you can’t get the brass Omni Robusta anymore that I would have to start there.

12-13-2025

I took the same setup I ran in the match last weekend and tested again but noticed that the set screw had backed out on it’s own and significantly dropped the cyclic rate down even more. From 608RPM to 532RPM. Yes, I did change ammo from my 155Gr reloads to my 147Gr reloads but don’t think that had much to do with it.

A customer was kind enough to lend me his Miculek buffer since they are so slow to ship. 10 business days to get it into USPS’s hands….and I’m still waiting.

The Miculek buffer has a set screw perpendicular to the bore to prevent the screw from backing out like what happened on my Omni Robusta buffer and so I tested with the max backed out position and it locked the bolt back with no problem so proceeded to test the cyclic rate and I’m amazed that it is under 600 RPM with only 12.2oz of total reciprocating mass.

I was also curious to see if it would cycle 115Gr without a suppressor and it ran fine.

I went back to my old ARS-EX setup with the RB5007 to get a feel for the difference. You can see it is running considerably faster than the two suppressed magnetic buffer setups I tested above. I think the ARS-EX setup feels softer to me on the rearward stroke as it is may not be bottoming out as seen in some of my videos and if it is, it is just barely doing so and the hydraulic action is greatly softening that impact. I think the magnetic is bottoming out. However, as seen above, I have not done much adjusting of the magnets yet. I presume that I could tighten it so that it cushions the impact more when bottoming out but will have to do more testing to see how much that may increase the cyclic rate. I don’t have that many rounds through the Miculek buffer yet but I think there is less to fail on it vs the Kynshot which I have had at least 3 where the ‘head’ falls off. Kynshot does replace them with no hassle though. It is early in my testing but I don’t see any apparent points of failure with the Miculek magnetic.